1. Ihe na-agba agba

(1) Titanium na ala alloys ya na-adịkarịghị ejiri nro dị nro kpuchie ya.Ọla brazing na-eji brazing bụ isi gụnyere ntọala ọla ọcha, ntọala aluminom, ntọala titanium ma ọ bụ ntọala zirconium titanium.

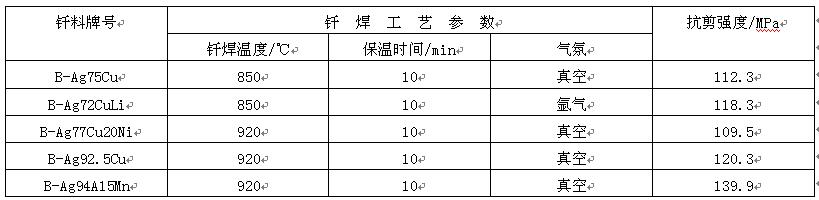

A na-eji ọla ọcha eme ihe maka akụrụngwa nwere okpomọkụ na-erughị 540 ℃.Njikọ ndị na-eji ọlaọcha ọlaọcha dị ọcha nwere ike dị ala, dị mfe ịgbawa, na nkwụsị nke corrosion na-adịghị mma na nkwụsị oxidation.Ọnọdụ okpomọkụ nke Ag Cu solder dị ala karịa nke ọla ọcha, mana wettability na-ebelata site na mmụba nke ọdịnaya Cu.The Ag Cu solder nwere obere ego Li nwere ike melite wettability na alloying ogo n'etiti solder na isi metal.AG Li solder nwere njirimara nke ebe mgbaze dị ala yana ike redicibility.Ọ dabara maka brazing titanium na titanium alloys na ikuku nchebe.Otú ọ dị, vacuum brazing ga-emerụ ọkụ n'ihi evaporation Li.Ag-5al- (0.5 ~ 1.0) Mn filler metal bụ ọkacha mma igwe ndochi maka ihe ndị dị mkpa titanium alloy.Njikọ brazed nwere ezigbo oxidation na nguzogide corrosion.Ike shiee nke titanium na nkwonkwo titanium alloy brazed na ọlaọcha base filler metal ka egosiri na Tebụl 12.

Tebụl 12 usoro brazing parameters na ike nkwonkwo nke titanium na titanium alloys

Okpomọkụ brazing nke aluminom dabeere solder dị ala, nke na-agaghị eme ka omume nke titanium alloy β Phase mgbanwe na-ebelata ihe ndị chọrọ maka nhọrọ nke brazing fixture ihe na ihe owuwu.Mmekọrịta dị n'etiti igwe na-ekpuchi ihe na ihe mgbakwasị ụkwụ dị ala, nkwụsịtụ na mgbasa ozi adịghị akọwapụta ya, ma plasticity nke metal filler dị mma, ọ dịkwa mfe ịkwanye ihe mkpuchi na ihe mgbakwasị ụkwụ ọnụ, ya mere ọ dị. dabara nke ọma maka brazing titanium alloy radiator, usoro ebuanu na usoro laminate.

Titanium dabeere ma ọ bụ titanium zirconium fluxes na-enwekarị Cu, Ni na ihe ndị ọzọ, nke nwere ike ịgbasa ngwa ngwa n'ime matriks wee meghachi omume na titanium n'oge brazing, na-ebute corrosion matrix na nhazi nke oyi akwa.Ya mere, a ghaghị ịchịkwa okpomọkụ nke brazing na oge njide n'oge brazing, na e kwesịghị iji ya mee ihe maka brazing nke ihe ndị nwere obere mgbidi ruo n'ókè o kwere mee.B-ti48zr48be bụ ihe a na-ahụkarị Ti Zr solder.Ọ nwere ezigbo wettability na titanium, na isi metal enweghị ọchịchọ nke ọka n'oge brazing.

(2) Brazing filler ọla maka zirconium na base alloys brazing nke zirconium na base alloys gụnyere b-zr50ag50, b-zr76sn24, b-zr95be5, wdg, nke a na-ejikarị na brazing nke zirconium alloy ọkpọkọ nke nuklia ike reactors.

(3) Ntugharị brazing na titanium ikuku na-echebe, zirconium na alloys ntọala nwere ike nweta nsonaazụ na-eju afọ na ikuku na ikuku inert (helium na argon).A ga-eji argon dị ọcha mee ihe maka brazing mkpuchi argon, ebe igirigi ga-abụrịrị -54 ℃ ma ọ bụ ala.Ọpụrụiche nwere fluoride na chloride metal Na, K na Li ga-ejirịrị maka ịgba ọkụ.

2. teknụzụ brazing

Tupu ịmalite brazing, a ga-ehichapụrịrị elu ahụ nke ọma, kpochapụ ma wepụ ihe nkiri oxide.A ga-ewepụ ihe nkiri oxide siri ike site na usoro igwe, usoro ịgba aja aja ma ọ bụ usoro ịsa nnu gbazere.Enwere ike ikpochapụ ihe nkiri oxide dị mkpa na ngwọta nwere 20% ~ 40% nitric acid na 2% hydrofluoric acid.

A naghị ekwe ka Ti, Zr na alloys ha jikọọ elu ikuku na ikuku n'oge kpo oku brazing.Enwere ike ịme brazing n'okpuru nchebe nke agụụ ma ọ bụ gas inert.Enwere ike iji kpo oku induction dị elu ma ọ bụ kpo oku na nchekwa.Igwe ọkụ induction bụ ụzọ kachasị mma maka obere akụkụ symmetrical, ebe brazing n'ime ọkụ na-aba uru maka nnukwu ihe dị mgbagwoju anya.

Ni Cr, W, Mo, Ta na ihe ndị ọzọ ka a ga-ahọrọ dị ka ihe na-ekpo ọkụ maka brazing Ti, Zr na alloys ha.A gaghị eji akụrụngwa nwere graphite ekpughere dị ka ihe ndị na-ekpo ọkụ iji zere mmetọ carbon.A ga-eji ihe ndị nwere ezigbo ike dị elu mee ihe nrụnye brazing, ọnụọgụ mgbasawanye ọkụ yiri nke Ti ma ọ bụ Zr, yana nrụgharị dị ala na metal ntọala.

Oge nzipu: Jun-13-2022