1. Ịkwụsị ike

Ngwongwo brazing nke aluminom na aluminom alloys adịghị mma, ọkachasị n'ihi na ihe nkiri oxide dị n'elu siri ike iwepụ.Aluminom nwere mmetụta dị mma maka ikuku oxygen.Ọ dị mfe ịmepụta ihe nkiri dị egwu, kwụsiri ike ma dị elu na-agbaze oxide Al2O3 n'elu.N'otu oge ahụ, aluminom alloys nwere magnesium ga-emekwa ka ihe nkiri oxide kwụsiri ike nke ukwuu MgO.Ha ga-egbochi nke ukwuu wetting na mgbasa nke solder.Na ike iwepu.N'oge brazing, a ga-eme usoro brazing naanị site na ngbanwe kwesịrị ekwesị.

Nke abuo, ọrụ nke aluminum na aluminum alloy brazing siri ike.Ebe mgbaze nke aluminum na aluminom alloy adịghị iche na nke metal brazing filler eji.Oke okpomọkụ nhọrọ maka brazing dị warara nke ukwuu.Obere njikwa okpomọkụ na-ekwesịghị ekwesị dị mfe ime ka ikpo ọkụ ma ọ bụ ọbụna na-agbaze nke metal ala, na-eme ka usoro brazing siri ike.Ụfọdụ alloys aluminom na-ewusi ike site na ọgwụgwọ okpomọkụ ga-emekwa ka ihe dị nro dị nro dị ka ịka nká ma ọ bụ nkwụsịtụ n'ihi ikpo ọkụ brazing, nke ga-ebelata ihe onwunwe nke nkwonkwo brazed.N'oge brazing ọkụ, ọ na-esiri ike ikpebi ọnọdụ okpomọkụ n'ihi na agba nke aluminum alloy adịghị agbanwe n'oge kpo oku, nke na-eme ka ihe ndị a chọrọ maka ọkwa ọrụ onye ọrụ.

Ọzọkwa, nguzogide corrosion nke aluminom na aluminom alloy brazed nkwonkwo na-emetụta ngwa ngwa site na ndochi igwe na fluxes.The electrode ikike nke aluminum na aluminum alloy dị nnọọ iche na nke solder, nke na-ebelata corrosion iguzogide nke nkwonkwo, karịsịa maka nro soldering nkwonkwo.Na mgbakwunye, ọtụtụ n'ime fluxes eji na brazing nke aluminum na aluminum alloys nwere ike corrosivity.Ọbụna ma ọ bụrụ na a na-ehicha ha mgbe brazing gasịrị, mmetụta nke fluxes na nguzogide corrosion nke nkwonkwo agaghị ekpochapụ kpamkpam.

2. Ihe na-agba agba

(1) Brazing nke aluminum na aluminum alloys bụ usoro a na-ejikarị eme ihe, n'ihi na ihe mejupụtara na ikike electrode nke brazing filler metal na base metal dị nnọọ iche, nke dị mfe ime ka electrochemical corrosion nke nkwonkwo.The soft soldering tumadi adopts zinc dabeere solder na tin lead solder, nke nwere ike kewaa n'ime ala okpomọkụ solder (150 ~ 260 ℃), ọkara okpomọkụ solder (260 ~ 370 ℃) na elu okpomọkụ solder (370 ~ 430 ℃) dị ka oke okpomọkụ.Mgbe a na-eji tin lead solder na ọla kọpa ma ọ bụ nickel ka etinyere ya n'elu aluminom maka brazing, enwere ike igbochi corrosion na nkwonkwo nkwonkwo, ka ọ wee melite nguzogide corrosion nke nkwonkwo.

A na-eji brazing nke aluminum na aluminom alloys eme ihe n'ọtụtụ ebe, dịka ntuziaka nzacha, evaporator, radiator na ihe ndị ọzọ.Naanị ihe mkpuchi aluminom nwere ike iji mee ihe maka brazing nke aluminom na aluminom alloys, n'ime nke aluminom silicon filler ọla ka a na-ejikarị.E gosipụtara ụdị ngwa ngwa a kapịrị ọnụ na ike ịkpụ nke nkwonkwo brazed na Tebụl 8 na tebụl 9 n'otu n'otu.Otú ọ dị, ebe mgbaze nke ihe nkedo a dị nso na nke metal ala, ya mere okpomọkụ okpomọkụ kwesịrị ịdị na-achịkwa nke ọma na n'ụzọ ziri ezi n'oge brazing iji zere ikpo ọkụ ma ọ bụ ọbụna na-agbaze nke metal ala.

Tebụl 8 ngwa ngwa nke ọla brazing filler maka aluminom na aluminom alloys

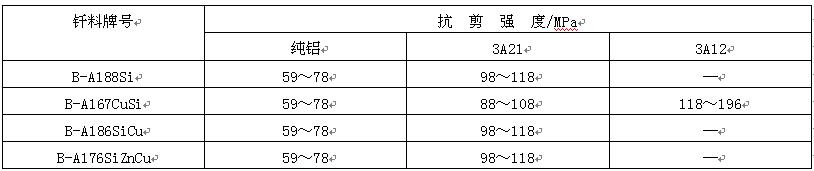

Tebụl 9 ike shiee nke aluminom na aluminom alloy nkwonkwo brazed na aluminum silicon filler ọla

A na-enyekarị ihe na-ere aluminom silicon n'ụdị ntụ ntụ, mado, waya ma ọ bụ mpempe akwụkwọ.N'ọnọdụ ụfọdụ, a na-eji efere ihe mejupụtara nke nwere aluminom dị ka isi na silicon silicon solder ka a na-eji ihe mkpuchi.A na-eji usoro hydraulic eme ụdị efere ihe a na-ere ihe, a na-ejikarị ya eme ihe dịka akụkụ nke ihe mgbochi brazing.N'oge brazing, metal brazing filler na efere ihe mejupụtara na-agbaze ma na-aga n'okpuru ọrụ nke capillary na ike ndọda iji mejupụta oghere nkwonkwo.

(2) Flux na gas na-echebe maka aluminum na aluminum alloy brazing, a na-ejikarị flux pụrụ iche wepụ ihe nkiri ahụ.A na-eji ihe ire ere dị nro na-ekpo ọkụ na-ekpo ọkụ na-adabere na triethanolamine, dị ka fs204.Uru nke mgbanwe a bụ na ọ nwere ntakịrị mmetụta corrosion na metal ntọala, ma ọ ga-emepụta nnukwu gas, nke ga-emetụta wetting na caulking nke ihe na-ere ahịa.A na-eji mgbagharị na-emeghachi omume dabere na zinc chloride, dị ka fs203 na fs220a, na-eji ọkara okpomọkụ na nnukwu okpomọkụ dị nro.Mgbanwe na-emeghachi omume na-emebi emebi nke ukwuu, na a ga-ewepụrịrị ihe fọdụrụ ya ka emechara brazing.

Ka ọ dị ugbu a, brazing nke aluminom na aluminom alloys ka na-achịkwa iwepụ ihe nkiri flux.Ntugharị brazing ejiri na-agụnye flux dabere na chloride na fluoride dabere.Mgbanwe nke chloride nwere ikike siri ike iwepu ihe nkiri oxide na mmiri dị mma, mana ọ nwere mmetụta na-emebi emebi na metal ala.A ga-ewepụrịrị ihe fọdụrụ ya kpamkpam ka emechara brazing.Fluoride dabeere flux bụ ụdị mgbanwe ọhụrụ, nke nwere mmetụta mwepụ ihe nkiri dị mma na enweghị corrosion na metal ala.Agbanyeghị, ọ nwere ebe mgbaze dị elu yana nkwụsi ike ọkụ na-adịghị mma, enwere ike iji ya naanị na silicon silicon solder.

Mgbe brazing aluminum na aluminum alloys, agụụ, nnọpụiche ma ọ bụ inert ikuku na-ejikarị.Mgbe a na-eji vacuum brazing, ogo agụụ ga-erukarị n'usoro nke 10-3pa.Mgbe a na-eji nitrogen ma ọ bụ argon gas maka nchebe, ịdị ọcha ya ga-adị elu nke ukwuu, ebe igirigi ga-adị ala karịa -40 ℃.

3. teknụzụ brazing

Brazing nke aluminom na aluminom alloys nwere nnukwu ihe achọrọ maka nhicha nke elu workpiece.Iji nweta ezigbo mma, a ga-ewepụ ntụpọ mmanụ na ihe nkiri oxide dị n'elu tupu ịkwa akwa.Wepu ntụpọ mmanụ n'elu ya na mmiri mmiri Na2CO3 na okpomọkụ nke 60 ~ 70 ℃ maka 5 ~ 10min, wee kpochaa ya na mmiri dị ọcha;Enwere ike wepu ihe nkiri oxide elu site na etching na NaOH aqueous solution na okpomọkụ nke 20 ~ 40 ℃ maka 2 ~ 4min, wee saa ya na mmiri ọkụ;Mgbe o wepụsịrị ntụpọ mmanụ na ihe nkiri oxide n'elu, a ga-eji mmiri HNO3 mee ihe na-arụ ọrụ maka gloss maka 2 ~ 5min, wee kpochaa ya na mmiri na-agba ọsọ ma mesịa kpọọ nkụ.Agaghị emetụ ihe ndị a na-arụ ọrụ nke usoro ndị a aka ma ọ bụ metọọ ya na unyi ndị ọzọ, a ga-akwakwa ya n'ime 6 ~ 8h.Ọ ka mma ịme braze ozugbo ma ọ bụrụ na ọ ga-ekwe omume.

Ụzọ brazing nke aluminom na aluminom alloys tumadi gụnyere ire ọkụ brazing, soldering ígwè brazing na oven brazing.Ụzọ ndị a n'ozuzu na-eji flux na brazing, ma nwee ihe ndị siri ike chọrọ na okpomọkụ kpo oku na oge ijide.N'oge a na-agba ọkụ ọkụ na ị na-ere ígwè brazing, zere ikpo ọkụ ozugbo site na isi iyi ọkụ iji gbochie mmịfe ahụ ka ọ ghara ikpo oke ọkụ na ọdịda.Ebe ọ bụ na aluminom nwere ike gbazee na solder dị nro na ọdịnaya zinc dị elu, a ghaghị ịkwụsị ikpo ọkụ ozugbo emechara njikọ ahụ iji zere mmebi metal dị ala.N'ọnọdụ ụfọdụ, brazing nke aluminum na aluminom alloys mgbe ụfọdụ anaghị eji flux, ma na-eji ultrasonic ma ọ bụ scraping ụzọ wepụ ihe nkiri.Mgbe ị na-eji scraping wepụ ihe nkiri maka brazing, buru ụzọ kpoo workpiece ahụ na okpomọkụ nke brazing, wee kpochapụ akụkụ brazing nke workpiece na njedebe nke mkpanaka solder (ma ọ bụ ngwá ọrụ scraping).Mgbe ị na-agbaji ihe nkiri oxide n'elu, njedebe nke ihe na-ere ahịa ga-agbaze ma mee ka ígwè dị ala.

Ụzọ brazing nke aluminom na aluminom alloys gụnyere tumadi brazing ire ọkụ, ọkụ brazing, itinye brazing, vacuum brazing na gas kpuchie brazing.A na-ejikarị brazing ọkụ eme ihe maka obere ọrụ na mmepụta otu ibe.Iji zere ọdịda nke mgbanwe ahụ n'ihi kọntaktị dị n'etiti adịghị ọcha na acetylene na flux mgbe ị na-eji ire ọkụ oxyacetylene, ọ dị mma iji mmanụ ọkụ ikuku abịakọrọ na obere reducibility iji gbochie oxidation nke metal ala.N'oge a kapịrị ọnụ brazing, brazing flux na filler metal nwere ike idobe n'ebe brazed tupu oge na-ekpo ọkụ n'otu oge na workpiece;The workpiece nwekwara ike kpụ ọkụ n'ọnụ na brazing okpomọkụ mbụ, na mgbe ahụ solder tinye na flux nwere ike iziga na brazing ọnọdụ;Mgbe igwe na-agbaze na ndochi ahụ gbazere, a ga-ewepụ ọkụ ọkụ na-ekpo ọkụ nke nta nke nta ka ejupụtachara ígwè ahụ.

Mgbe ị na-eme brazing aluminum na aluminum alloy n'ime ọkụ ikuku, brazing filler metal ga-abụ nke edoziri, na brazing flux ga-agbaze na mmiri distilled iji dozie ngwọta siri ike na ntinye nke 50% ~ 75%, wee kpuchie ma ọ bụ fesa ya. elu brazing.A pụkwara ikpuchi ntụ ntụ ntụ ntụ kwesịrị ekwesị na metal brazing filler na brazing elu, mgbe ahụ, a ga-etinye weldment gbakọtara n'ime ọkụ maka ikpo ọkụ.Iji gbochie ígwè isi ka ọ ghara ikpo ọkụ ma ọ bụ ọbụna na-agbaze, a ghaghị ịchịkwa okpomọkụ ọkụ.

A na-ejikarị tapawa ma ọ bụ foil solder eme ihe maka itinye brazing nke aluminom na aluminom alloys.A ga-ekpochasị ihe a na-arụkọ ọrụ ọnụ tupu ya enwee brazing iji mee ka ọnọdụ okpomọkụ ya dị nso na brazing okpomọkụ, wee mikpuo ya na brazing flux maka brazing.N'oge brazing, okpomọkụ brazing na oge brazing ga-achịkwa nke ọma.Ọ bụrụ na okpomọkụ dị oke elu, ígwè isi dị mfe igbari na ihe na-ere ahịa dị mfe ịla n'iyi;Ọ bụrụ na ọnọdụ okpomọkụ dị oke ala, ihe na-ere ahịa adịghị agbaze nke ọma, ọnụ ọgụgụ brazing na-ebelata.A ga-ekpebi okpomoku brazing dị ka ụdị na nha nke metal ntọala, ihe mejupụtara na ebe na-agbaze nke igwe na-ejuputa, na n'ozuzu n'etiti mmiri ọkụ nke mmiri na-ekpo ọkụ na ihe siri ike nke metal metal.Oge ntinye nke workpiece na bath flux ga-ahụrịrị na onye na-ere ahịa nwere ike gbazee ma na-asọba, na oge nkwado ekwesịghị ịdị ogologo.Ma ọ bụghị ya, ihe silicon nke dị na solder nwere ike ịgbasa n'ime metal ala, na-eme ka metal dị n'akụkụ ọnụ mmiri ahụ na-agbaji.

Na vacuum brazing nke aluminom na aluminum alloys, metal arụ ọrụ activators na-ejikarị gbanwee elu oxide film nke aluminom na hụ na wetting na mgbasa nke solder.Enwere ike iji Magnesium mee ihe ozugbo na workpiece n'ụdị irighiri ihe, ma ọ bụ weba ya n'ime mpaghara brazing n'ụdị uzuoku, ma ọ bụ enwere ike itinye magnesium na ihe nrịbama silicon silicon dị ka ihe alloy.N'ihi na workpiece nwere mgbagwoju Ọdịdị, iji hụ na zuru mmetụta nke magnesium vapor na isi metal ma melite brazing mma, mpaghara ọta usoro a na-emekarị ihe, ya bụ, a na-ebu ụzọ tinye workpiece n'ime igbe igwe anaghị agba nchara (ọkachamara). mara dị ka igbe usoro), wee tinye ya n'ime ọkụ ọkụ maka ikpo ọkụ brazing.Vacuum Brazed Aluminom na aluminum alloy nkwonkwo nwere ezigbo elu na nnukwu brazed nkwonkwo, na ọ dịghị mkpa ka ihicha mgbe brazing;Otú ọ dị, akụrụngwa brazing na-ekpo ọkụ dị oke ọnụ, na magnesium vapor na-emerụ ọkụ ahụ nke ọma, n'ihi ya, ọ dị mkpa ka a na-ehicha ma na-echekwa ya ugboro ugboro.

Mgbe brazing aluminum na aluminum alloys na nnọpụiche ma ọ bụ inert ikuku, magnesium activator ma ọ bụ flux nwere ike iji wepụ ihe nkiri.Mgbe a na-eji magnesium activator wepụ ihe nkiri ahụ, ọnụọgụ magnesium chọrọ dị ala karịa nke ikuku brazing.N'ozuzu, w (mg) bụ ihe dịka 0.2% ~ 0.5%.Mgbe ọdịnaya nke magnesium dị elu, ịdị mma nke nkwonkwo ga-ebelata.Usoro NOCOLOK brazing site na iji fluoride flux na nchebe nitrogen bụ usoro ọhụrụ emepụtara ngwa ngwa n'afọ ndị na-adịbeghị anya.Ebe ọ bụ na ihe fọdụrụ nke fluoride flux anaghị amịkọrọ mmiri na ọ bụghị ihe na-emebi emebi na aluminom, enwere ike ịhapụ usoro iwepụ ihe fọdụrụnụ mgbe brazing gasịrị.N'okpuru nchebe nke nitrogen, ọ bụ naanị obere obere fluoride flux kwesịrị ka a na-ekpuchi ya, metal filler nwere ike ime ka metal dị ala na-adaba nke ọma, ọ dịkwa mfe ịnweta nkwonkwo brazed dị elu.Ka ọ dị ugbu a, a na-eji usoro brazing NOCOLOK a mee ihe na mmepụta nke aluminum radiators na ihe ndị ọzọ.

Maka aluminom na aluminom alloy brazed na fluoride na-abụghị fluoride flux, a ga-ewepụrịrị ihe fọdụrụ n'ime mmiri ka emechara brazing.Enwere ike iji ihe ngwọta organic dị ka methanol na trichlorethylene sachaa ihe fọdụrụ na mmiri brazing organic, ma mee ka mmiri dị ọkụ na mmiri oyi kpochaa ya.Chloride bụ ihe fọdụrụ nke brazing flux maka aluminom, nke enwere ike wepu ya dịka ụzọ ndị a si dị;Nke mbụ, gbanye na mmiri ọkụ na 60 ~ 80 ℃ maka 10min, jiri nlezianya hichaa ihe fọdụrụ na nkwonkwo brazed na ahịhịa, ma kpochaa ya na mmiri oyi;Wee tinye ya na 15% nitric acid aqueous solution maka nkeji iri atọ, wee sachaa ya na mmiri oyi.

Oge nzipu: Jun-13-2022