1. Ihe na-agba agba

(1)Brazing nke carbon ígwè na obere alloy ígwè gụnyere brazing dị nro na brazing siri ike.Ihe ire ere nke a na-ejikarị eme ihe n'ụdị ire ere bụ tin lead solder.Mmiri mmiri nke ihe nrịcha a na nchara na-abawanye site na mmụba nke ọdịnaya tin, ya mere a ga-eji ihe na-ere ihe nke nwere nnukwu tin mee ihe maka mkpuchi nkwonkwo.Enwere ike ịmepụta oyi akwa intermetallic Fesn2 na interface dị n'etiti tin na ígwè n'ime tin lead solder.Iji zere nguzobe nke ngwakọta na oyi akwa a, ekwesịrị ịchịkwa okpomọkụ brazing na oge njide nke ọma.The shiee ike nke carbon ígwè nkwonkwo brazed na ọtụtụ ahụkarị tin lead solders ka egosiri na Isiokwu 1. N'ime ha, nkwonkwo ike brazed na 50% w (SN) bụ nke kasị elu, na nkwonkwo ike welded na antimony free solder dị elu karịa. na antimony.

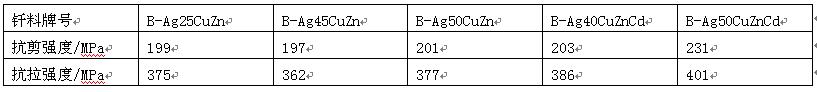

Tebụl 1 ike shiee nke nkwonkwo carbon ígwè ejiri tin lead solder brazed

Mgbe brazing carbon steel na obere alloy ígwè, ọla kọpa dị ọcha, ọla kọpa zinc na ọla kọpa ọla kọpa zinc brazing filler ọla na-ejikarị.Ọla kọpa dị ọcha nwere ebe mgbaze dị elu ma dị mfe oxidize metal base n'oge brazing.A na-eji ya eme ihe maka brazing mkpuchi gas na oghere brazing.Otú ọ dị, ekwesịrị iburu n'uche na ọdịiche dị n'etiti nkwonkwo brazed kwesịrị ịbụ ihe na-erughị 0.05mm iji zere nsogbu nke na-enweghị ike imejupụta oghere nkwonkwo n'ihi ezigbo mmiri mmiri nke ọla kọpa.The carbon ígwè na ala alloy ígwè nkwonkwo brazed na dị ọcha ọla kọpa nwere nnukwu ike.N'ozuzu, ike shiee bụ 150 ~ 215mpa, ebe ike ike na-ekesa n'etiti 170 ~ 340mpa.

E jiri ya tụnyere ọla kọpa dị ọcha, ebe mgbaze nke ọla kọpa zinc solder na-ebelata n'ihi mgbakwunye nke Zn.Iji gbochie evaporation Zn n'oge brazing, n'otu aka ahụ, enwere ike ịgbakwunye obere Si na ọla kọpa zinc solder;N'aka nke ọzọ, a ga-eji ụzọ kpo oku ngwa ngwa, dị ka ire ọkụ ọkụ, brazing induction na itinye brazing.Njikọ nke carbon ígwè na obere alloy ígwè brazed na ọla kọpa zinc filler metal nwere ezigbo ike na plasticity.Dị ka ọmụmaatụ, ike tensile na shiee ike nke carbon ígwè nkwonkwo brazed na b-cu62zn solder ruru 420MPa na 290mpa.Ebe mgbaze nke ọdụ ọla kọpa ọlaọcha dị ala karịa nke ọla kọpa zinc solder, nke dabara adaba maka ịgbado agịga.Igwe nkpuchi a dabara adaba maka ire ọkụ ọkụ, induction brazing na ọkụ ọkụ brazing nke carbon steel na alloy steel dị ala, mana ọdịnaya nke Zn kwesịrị ibelata dị ka o kwere mee n'oge ọkụ ọkụ, na ọkụ ọkụ kwesịrị ịbawanye ọnụego ọkụ.Brazing carbon steel na alloy dị ala nwere ọla ọla kọpa ọla kọpa zinc nwere ike nweta nkwonkwo nwere ike dị mma na plastik.Edepụtara data akọwapụtara na tebụl 2.

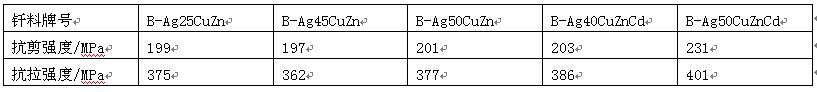

Tebụl 2 ike nke obere carbon ígwè nkwonkwo brazed na ọlaọcha ọla kọpa zinc solder

(2) Flux: flux ma ọ bụ mkpuchi gas ga-eji brazing carbon ígwè na ala alloy ígwè.A na-ekpebikarị mgbanwe a site na igwe ndochi ahọpụtara na usoro brazing.Mgbe a na-eji tin lead solder, enwere ike iji mmiri mmiri agwakọta nke zinc chloride na ammonium chloride mee ihe dị ka mgbagharị ma ọ bụ mgbanwe pụrụ iche.Ihe fọdụrụ na ntugharị a na-abụkarị ihe na-emebi emebi, na nkwonkwo kwesịrị ihicha ya nke ọma ka emechara brazing.

Mgbe brazing na ọla kọpa zinc filler metal, fb301 ma ọ bụ fb302 flux ga-ahọrọ, ya bụ, borax ma ọ bụ ngwakọta nke borax na boric acid;Na brazing ọkụ, ngwakọta nke methyl borate na formic acid nwekwara ike iji dị ka brazing flux, nke B2O3 vapor na-arụ ọrụ nke iwepụ ihe nkiri.

Mgbe ejiri ọla ọla kọpa zinc brazing filler metal, fb102, fb103 na fb104 brazing fluxes nwere ike họrọ, ya bụ, ngwakọta nke borax, boric acid na ụfọdụ fluorides.Ihe fọdụrụ n'ime mmiri a na-emebi emebi ruo n'ókè ụfọdụ, a ga-ewepụkwa ya ma emesịa ya.

2. teknụzụ brazing

A ga-ehicha elu elu nke a ga-agbado site na usoro igwe ma ọ bụ kemịkalụ iji hụ na e wepụrụ ihe nkiri oxide na ihe ndị dị ndụ kpamkpam.Elu a kpochara agaghị adị oke siri ike ma ghara ịrapara na ibe igwe ma ọ bụ unyi ndị ọzọ.

Carbon ígwè na obere alloy ígwè nwere ike brazed site dị iche iche na-emekarị brazing ụzọ.Mgbe a na-agba ọkụ, ekwesịrị iji nnọpụiche ma ọ bụ ibelata ntakịrị ọkụ.N'oge a na-arụ ọrụ, a ga-ezere ikpo ọkụ nke metal filler na ọkụ ọkụ dị ka o kwere mee.Ụzọ kpo oku ngwa ngwa dị ka induction brazing na itinye brazing dabara adaba nke ukwuu maka brazing nke igwe anaghị agbanyụ na ọkụ.N'otu oge ahụ, a ga-ahọrọ quenching ma ọ bụ brazing na okpomọkụ dị ala karịa iwe ọkụ ka ọ ghara ime ka ígwè dị nro dị nro.Mgbe brazing ala alloy elu ígwè dị elu na ikuku na-echebe, ọ bụghị naanị elu ịdị ọcha nke gas ka a chọrọ, kamakwa gas flux ga-eji hụ na wetting na-agbasa nke filler metal n'elu nke isi metal.

Enwere ike wepu ntughari nke fọduru site na usoro kemịkalụ ma ọ bụ igwe.Enwere ike ihichapụ ma ọ bụ hichaa ihe fọdụrụ nke organic brazing flux site na mmanụ ụgbọala, mmanya, acetone na ihe mgbaze ndị ọzọ;A ga-ewepụ ihe ndị fọdụrụ na mmiri na-emebi emebi siri ike dị ka zinc chloride na ammonium chloride na mmiri mmiri NaOH, wee kpochaa ya na mmiri ọkụ na oyi;Boric acid na boric acid flux residues siri ike iwepu, na enwere ike idozi ya site na usoro igwe ma ọ bụ imikpu ogologo oge n'ime mmiri na-ebili.

Oge nzipu: Jun-13-2022