1. Ihe na-agba agba

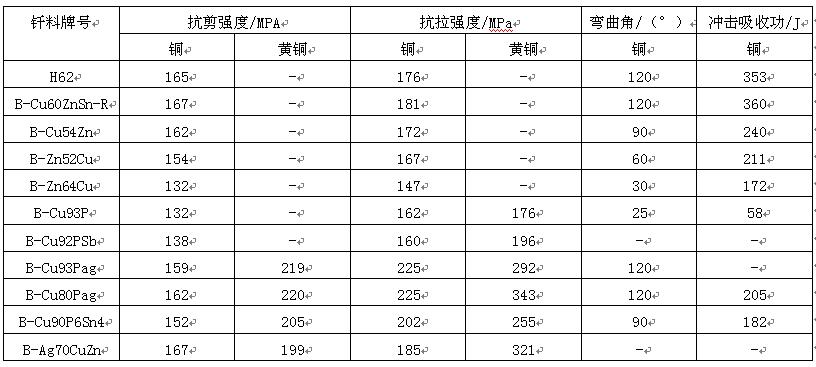

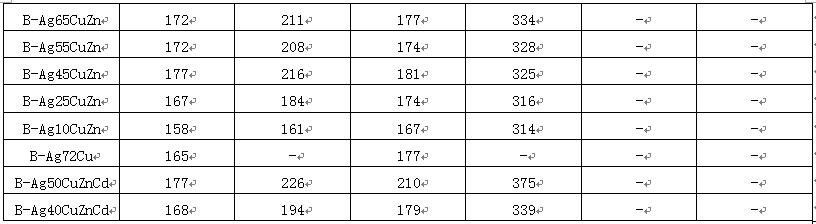

(1) E gosipụtara ike njikọ nke ọtụtụ ndị na-ere ọla kọpa na brass brazing na tebụl 10.

Tebụl 10 ike nke ọla kọpa na nkwonkwo brazed brass

Mgbe ị na-eji ọla kọpa brazing na tin lead solder, enwere ike họrọ flux brazing na-adịghị emebi emebi dị ka ngwọta mmanya rosin ma ọ bụ rosin na-arụ ọrụ na zncl2+nh4cl mmiri mmiri. A pụkwara iji nke ikpeazụ mee brazing brass, bronze and beryllium bronze. Mgbe brazing aluminum brass, aluminum bronze and silicon brass, brazing flux nwere ike ịbụ zinc chloride hydrochloric acid ngwọta. Mgbe ị na-agbaze ọla kọpa ọcha manganese, onye na-ahụ maka ịgba ọgwụ nwere ike ịbụ ngwọta phosphoric acid. Enwere ike iji ngwọta mmiri nke Zinc chloride dị ka mgbanwe mgbe ị na-eji ígwè na-eme ihe na-eme ihe na-eme brazing, yana fs205 flux nwere ike iji ya mee ihe mgbe ị na-eji ọla cadmium eme ihe.

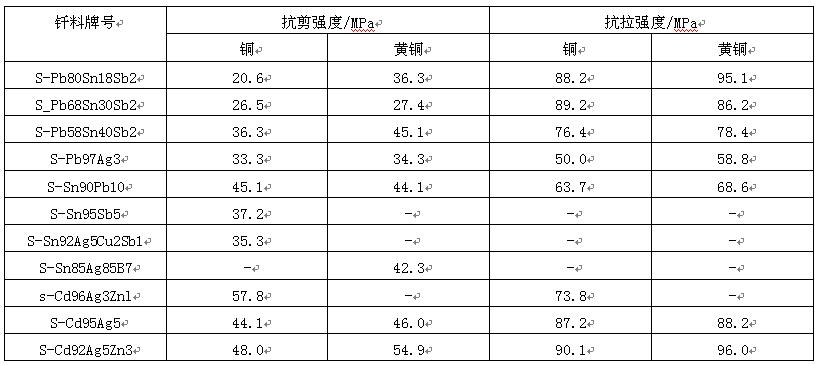

(2) Mgbe brazing ọla kọpa na brazing filler ọla na fluxes, ọlaọcha dabeere filler ọla na ọla kọpa site filler ọla nwere ike iji. Ọlaọcha dabere solder bụ ihe a na-ejikarị eme ihe siri ike n'ihi ebe mgbaze ya na-agafeghị oke, nhazi nhazi dị mma, ihe eji arụ ọrụ dị mma, ọkụ eletrik na ọkụ ọkụ. N'ihi na workpiece chọrọ elu conductivity, a ga-ahọrọ b-ag70cuzn solder nwere nnukwu ọlaọcha ọdịnaya. Maka brazing vacuum brazing ma ọ bụ brazing n'ime ọkụ ikuku nchekwa, a ga-ahọrọ b-ag50cu, b-ag60cusn na ihe mkpuchi ndị ọzọ na-enweghị ihe na-agbanwe agbanwe. Ọla brazing filler nwere obere ọla ọcha dị ọnụ ala, nwere okpomọkụ brazing dị elu yana adịghị ike nke nkwonkwo brazed. A na-ejikarị ha eme ihe maka brazing ọla kọpa na ọla kọpa alloys nwere obere ihe achọrọ. Ọla kọpa na ọla kọpa phosphorous silver brazing filler nwere ike iji naanị maka brazing ọla kọpa na ọla kọpa ya. N'ime ha, b-cu93p nwere mmiri mmiri dị mma ma jiri ya mee ihe maka akụkụ brazing anaghị emetụta ibu ọrụ na Electromechanical, ngwá ọrụ na ụlọ ọrụ mmepụta ihe. Oghere kachasị mma bụ 0.003 ~ 0.005mm. Ọla ọla kọpa phosphorous silver brazing filler metals (dị ka b-cu70pag) nwere ike na conductivity ka mma karịa ọla kọpa phosphorus brazing filler ọla. A na-ejikarị ha eme ihe maka nkwonkwo eletrik na ihe ndị dị elu chọrọ. Tebụl 11 na-egosi njiko nke ọtụtụ ihe brazing a na-ejikarị eme ọla kọpa na ọla.

Isiokwu 11 Njirimara nke ọla kọpa na brass brazed nkwonkwo

Oge nzipu: Jun-13-2022