1. Solder

Enwere ike iji ụdị ire ere niile nwere ọnọdụ okpomọkụ dị ala karịa 3000 ℃ maka W brazing, yana ọla kọpa ma ọ bụ ọla ọcha nwere ike iji maka akụrụngwa nwere okpomọkụ dị ala karịa 400 ℃;Gold dabeere, manganese dabeere, manganese dabeere, palladium dabeere ma ọ bụ akuakuzinwo dabeere metal filler na-ejikarị maka components eji n'etiti 400 ℃ na 900 ℃;Maka ihe eji eme ihe n'elu 1000 ℃, a na-ejikarị ọla dị ọcha dịka Nb, Ta, Ni, Pt, PD na Mo.Okpomọkụ na-arụ ọrụ nke akụrụngwa ejiri platinum base solder erutela 2150 ℃.Ọ bụrụ na 1080 ℃ mgbasa ọgwụgwọ a rụrụ mgbe brazing, kacha arụ ọrụ okpomọkụ nwere ike iru 3038 ℃.

Ọtụtụ n'ime ndị na-ere ahịa na-eji brazing w nwere ike iji brazing Mo, na ọla kọpa ma ọ bụ ọlaọcha dabere solders nwere ike iji maka Mo components na-arụ ọrụ n'okpuru 400 ℃;Maka ngwaọrụ eletrọnịkị na akụkụ ndị na-abụghị akụkụ na-arụ ọrụ na 400 ~ 650 ℃, Cu Ag, Au Ni, PD Ni ma ọ bụ Cu Ni solders nwere ike iji;Enwere ike iji titanium dabere ma ọ bụ ọla ndị ọzọ dị ọcha nke nwere ihe mgbaze dị elu maka ihe ndị na-arụ ọrụ na okpomọkụ dị elu.Ekwesiri iburu n'uche na manganese dabere, cobalt na nickel na-ejuputa ọla anaghị akwadokarị iji zere nguzobe nke ogige intermetallic na-emebi emebi na nkwonkwo brazing.

Mgbe TA ma ọ bụ Nb components na-eji n'okpuru 1000 ℃, ọla kọpa dabeere, manganese dabeere, cobalt dabeere, titanium dabeere, nickel dabeere, gold dabeere na palladium dabeere injections nwere ike họrọ, gụnyere Cu Au, Au Ni, PD Ni na Pt Au_ Ni na Ndị na-ere Cu Sn nwere ezigbo wettability na TA na Nb, ezigbo brazing seams akpụ na ike nkwonkwo dị elu.Dị ka ọla ndị na-ejuputa ọlaọcha na-emekarị ka ọla brazing na-akụkụ, ekwesịrị ịzere ha dịka o kwere mee.Maka ihe eji eme ihe n'etiti 1000 ℃ na 1300 ℃, ọla dị ọcha Ti, V, Zr ma ọ bụ alloys dabere na ọla ndị a na-etolite siri ike na mmiri mmiri na ha ka a ga-ahọrọ dị ka ọla brazing filler.Mgbe okpomọkụ ọrụ dị elu, enwere ike ịhọrọ igwe ndochi nwere HF.

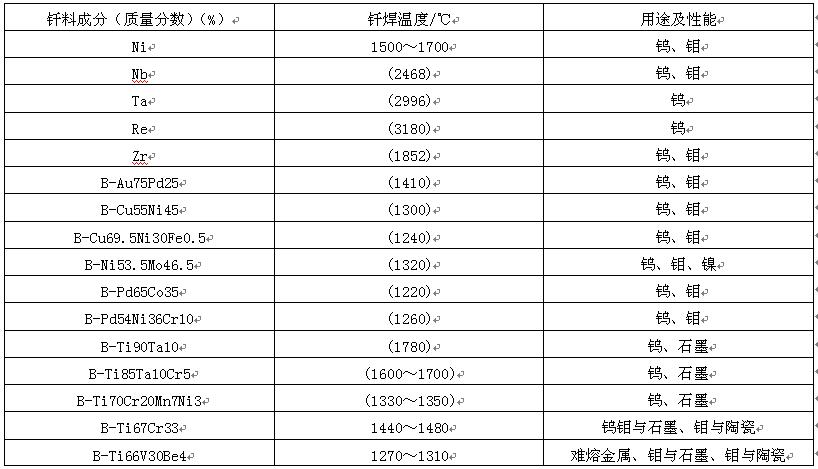

W. Lee tebụl 13 maka metal brazing filler maka Mo, Ta na Nb na oke okpomọkụ.

Tebụl 13 brazing filler metals maka oke okpomoku brazing nke ọla ndị na-emegharị emegharị

Tupu brazing, a chọrọ iji nlezianya wepụ oxide n'elu metal refractory.Enwere ike iji igwe na-egweri igwe, mgbawa ájá, nhicha ultrasonic ma ọ bụ ihicha kemịkalụ.A ga-eme brazing ozugbo usoro ihichachara.

N'ihi nbibi dị n'ime ya nke W, a ga-edozi akụkụ w nke ọma na ọrụ mgbakọ akụrụngwa iji zere nkwụsị.Iji gbochie nguzobe tungsten carbide na-agbaji agbaji, ekwesịrị izere kọntaktị ozugbo n'etiti W na graphite.Prestressing n'ihi tupu ịgbado ọkụ nhazi ma ọ bụ ịgbado ọkụ ka a ga-ewepụ tupu ịgbado ọkụ.W dị mfe oxidize mgbe okpomọkụ na-ebili.Ogo agụụ ga-adị elu nke ọma n'oge brazing.Mgbe a na-eme brazing n'ime oke okpomọkụ nke 1000 ~ 1400 ℃, ogo nke agụụ agaghị abụ ihe na-erughị 8 × 10-3Pa. Iji meziwanye okpomọkụ na-agbaze na okpomọkụ ọrụ nke nkwonkwo, a ga-ejikọta usoro brazing na ya. ọgwụgwọ mgbasa mgbe ịgbado ọkụ.Ọmụmaatụ, b-ni68cr20si10fel solder na-eji braze W na 1180 ℃.Mgbe atọ mgbasa ọgwụgwọ nke 1070 ℃ / 4h, 1200 ℃ / 3.5h na 1300 ℃ / 2h mgbe ịgbado ọkụ, ọrụ okpomọkụ nke brazed nkwonkwo nwere ike iru ihe karịrị 2200 ℃.

Ekwesịrị iburu n'uche obere ọnụọgụ nke mgbasawanye thermal mgbe ị na-agbakọta nkwonkwo brazed nke Mo, na oghere nkwonkwo kwesịrị ịdị n'ime oke nke 0.05 ~ 0.13MM.Ọ bụrụ na ejiri ihe nrụnye, họrọ ihe nwere obere ọnụọgụ nke mgbasawanye ọkụ.Mo recrystallization na-eme mgbe ire ọkụ brazing, ọkụ ikuku a na-achịkwa, ọkụ ọkụ, ọkụ induction na ikpo ọkụ na-eguzogide karịrị okpomọkụ recrystallization ma ọ bụ recrystallization okpomọkụ na-ebelata n'ihi mgbasa nke ihe na-ere ihe.Ya mere, mgbe brazing okpomọkụ dị nso na recrystallization okpomọkụ, ka oge brazing dị mkpụmkpụ, ka mma.Mgbe ị na-eme braz n'elu okpomoku recrystallization nke Mo, a ga-achịkwa oge brazing na ọnụego jụrụ oyi ka ịzenarị mgbawa nke oyi na-atụ ngwa ngwa kpatara.Mgbe a na-eji brazing ire ọkụ oxyacetylene, ọ dị mma iji ngwakọta agwakọta, ya bụ, borate ụlọ ọrụ ma ọ bụ ọlaọcha brazing flux gbakwunyere okpomọkụ dị elu nwere calcium fluoride, nke nwere ike nweta ezigbo nchebe.Usoro a bụ ibu ụzọ yikwasị akwa oyi akwa brazing flux n'elu Mo, wee yikwasị mgbawa okpomọkụ dị elu.Ọlaọcha brazing flux nwere ọrụ na oke okpomọkụ dị ala, yana okpomọkụ na-arụ ọrụ nke oke okpomọkụ nwere ike iru 1427 ℃.

Ngwa TA ma ọ bụ Nb na-akacha mma brazed n'okpuru agụụ, na ohere agụụ adịghị erughị 1.33 × 10-2Pa.Ọ bụrụ na a na-eme brazing n'okpuru nchebe nke gas inert, a ga-ewepụrịrị ihe ndị na-adịghị ọcha gas dị ka carbon monoxide, amonia, nitrogen na carbon dioxide.Mgbe a na-eme brazing ma ọ bụ nguzogide n'ikuku, a ga-eji metal brazing pụrụ iche na flux kwesịrị ekwesị.Iji gbochie TA ma ọ bụ Nb site na ịkpọtụrụ oxygen na okpomọkụ dị elu, a pụrụ ịkwanye akwa ọla kọpa ma ọ bụ nickel n'elu ma nwee ike ịme ọgwụgwọ na-ekpo ọkụ na-agbasa.

Oge nzipu: Jun-13-2022