Brazing nke igwe anaghị agba nchara

1. Ịkwụsị ike

Nsogbu bụ isi na brazing igwe anaghị agba nchara bụ na ihe nkiri oxide dị n'elu na-emetụta oke mmiri na ịgbasa ihe na-ere ya.Igwe anaghị agba nchara dị iche iche nwere Cr buru ibu, ụfọdụ nwekwara Ni, Ti, Mn, Mo, Nb na ihe ndị ọzọ, nke nwere ike ịmepụta ụdị oxides dị iche iche ma ọ bụ ọbụna oxides mejupụtara n'elu.N'ime ha, oxides Cr2O3 na TiO2 nke Cr na Ti kwụsiri ike ma sie ike iwepụ.Mgbe ị na-eme brazing na ikuku, a ga-eji mmiri na-arụ ọrụ wepụ ha;Mgbe ị na-eme brazing na ikuku nchebe, enwere ike ibelata ihe nkiri oxide naanị na ikuku dị ọcha na ebe igirigi dị ala na oke okpomọkụ;Na oghere brazing, ọ dị mkpa inwe oghere zuru oke na okpomọkụ zuru oke iji nweta mmetụta brazing dị mma.

Nsogbu ọzọ nke igwe anaghị agba nchara brazing bụ na ikpo ọkụ na-ekpo ọkụ na-enwe mmetụta dị ukwuu na nhazi nke isi ígwè.Igwe ọkụ na-ekpo ọkụ na-ekpo ọkụ nke austenitic igwe anaghị agba nchara agaghị adị elu karịa 1150 ℃, ma ọ bụghị na ọka ga-eto nke ọma;Ọ bụrụ na igwe anaghị agba nchara austenitic enweghị mmewere Ti ma ọ bụ Nb kwụsiri ike ma nwee ọdịnaya carbon dị elu, a ga-ezerekwa brazing n'ime okpomọkụ uche (500 ~ 850 ℃).Iji gbochie nguzogide corrosion ka ọ ghara ibelata n'ihi mmiri ozuzo nke chromium carbide.Nhọrọ nke brazing okpomọkụ maka martensitic igwe anaghị agba nchara bụ ihe siri ike.Otu bụ iji kwekọọ na okpomọkụ nke brazing na okpomọkụ na-ekpo ọkụ, iji jikọta usoro brazing na usoro ọgwụgwọ okpomọkụ;Nke ọzọ bụ na brazing okpomọkụ kwesịrị ịdị ala karịa okpomọkụ okpomọkụ iji gbochie metal ala ka ọ dị nro n'oge brazing.Ụkpụrụ nhọrọ okpomọkụ brazing nke mmiri ozuzo hardening igwe anaghị agba nchara bụ otu ihe ahụ nke martensitic igwe anaghị agba nchara, ya bụ, brazing okpomọkụ ga-adaba na usoro ọgwụgwọ okpomọkụ iji nweta ihe kacha mma n'ibu.

Na mgbakwunye na isi nsogbu abụọ a dị n'elu, enwere ọnọdụ nke mgbawa nrụgide mgbe ị na-eme brazing austenitic igwe anaghị agba nchara, ọkachasị mgbe ị na-eji ọla ọla kọpa zinc na-eme brazing.Iji zere mgbawa nrụgide, a ga-ewepụ ihe arụrụ arụ ahụ n'ihu brazing, na workpiece ga-ekpo ọkụ n'otu n'otu n'oge brazing.

2. Ihe na-agba agba

(1) Dabere na ihe achọrọ nke igwe anaghị agba nchara, ọla brazing filler a na-ejikarị eme ihe maka igwe anaghị agba nchara gụnyere Tin Lead brazing filler metal, silver based brazing filler metal, ọla kọpa dabere brazing filler metal, manganese dabeere brazing filler metal, nickel dabeere metal brazing filler na metal brazing filler metal dị oké ọnụ ahịa.

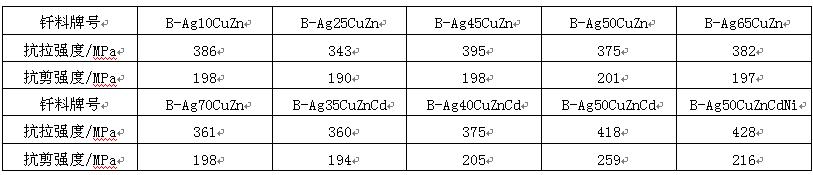

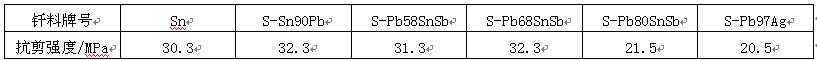

A na-eji tin lead solder eme ihe maka ịgbanye igwe anaghị agba nchara, ọ dịkwa mma ịnwe ọdịnaya tin dị elu.Ka ọdịnaya tin nke ihe na-ere ahịa na-adị elu, otú ahụ ka ọ na-adị mma na mmiri anaghị agba nchara.Ike shear nke 1Cr18Ni9Ti igwe anaghị agba nchara brazed with many common tin lead solders ka edepụtara na Tebụl 3. N'ihi ike dị ala nke nkwonkwo, a na-eji ha naanị maka akụkụ brazing nwere obere ikike ibu.

Tebụl 3 ike shiee nke 1Cr18Ni9Ti igwe anaghị agba nchara nchara na tin lead solder

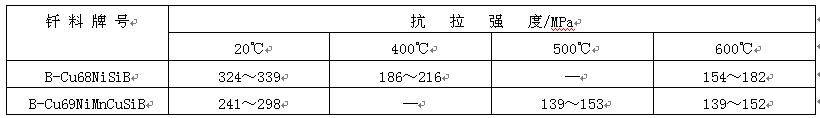

Ọla igwe na-ejuputa ọlaọcha bụ ọla ndochi a na-ejikarị eme ihe maka brazing igwe anaghị agba nchara.N'ime ha, ọla kọpa ọla kọpa zinc na ọla kọpa ọla kọpa zinc cadmium filler ọla na-ejikarị eme ihe n'ihi na okpomọkụ brazing enweghị mmetụta dị nta na njirimara nke metal ala.Ike nke ICr18Ni9Ti igwe anaghị agba nchara nkwonkwo brazed na ọtụtụ nkịtị silver dabeere solders e depụtara na Isiokwu 4. The igwe anaghị agba nchara nkwonkwo brazed na ọlaọcha dabeere solders na-adịkarịghị eji na ukwuu corrosive media, na-arụ ọrụ okpomọkụ nke nkwonkwo n'ozuzu adịghị gafere 300 ℃. .Mgbe ị na-eme brazing igwe anaghị agba nchara na-enweghị nickel, iji gbochie corrosion nke nkwonkwo brazed na gburugburu iru mmiri, a ga-eji brazing filler metal na nickel karịa, dị ka b-ag50cuzncdni.Mgbe ị na-eme brazing martensitic igwe anaghị agba nchara, iji gbochie nro nke isi metal, a ga-eji brazing filler metal na brazing okpomọkụ na-erughị 650 ℃, dị ka b-ag40cuzncd.Mgbe ị na-eme brazing igwe anaghị agba nchara na ikuku nchebe, iji wepụ ihe nkiri oxide n'elu, enwere ike iji lithium nwere brazing nke onwe ya, dịka b-ag92culi na b-ag72culi.Mgbe brazing igwe anaghị agba nchara na agụụ, iji mee ka ihe ndochi ka nwere ezigbo wettability mgbe ọ na-enweghị ihe ndị dị otú ahụ dị ka Zn na CD ndị dị mfe ikpochapụ, ọlaọcha filler metal nwere ihe ndị dị ka Mn, Ni na RD nwere ike ịbụ. họrọ.

Tebụl 4 ike nke ICr18Ni9Ti igwe anaghị agba nchara brazed na ọlaọcha dabere metal filler

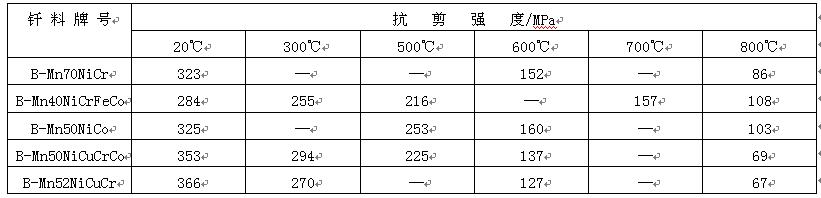

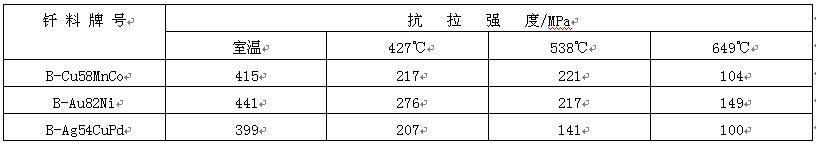

Ọla ọla kọpa ejiri mee brazing nchara dị iche iche bụ ọla kọpa dị ọcha, ọla kọpa nickel na ọla kọpa manganese cobalt brazing filler ọla.A na-eji ọla kọpa brazing dị ọcha eme ihe maka brazing n'okpuru nchebe gas ma ọ bụ oghere.Na-arụ ọrụ okpomọkụ nke igwe anaghị agba nchara nkwonkwo bụghị ihe karịrị 400 ℃, ma nkwonkwo nwere ogbenye ọxịdashọn nguzogide.A na-ejikarị ọla kọpa nickel brazing filler eme ihe maka ire ọkụ na induction brazing.A na-egosi ike nke brazed 1Cr18Ni9Ti igwe anaghị agba nchara na tebụl 5. Enwere ike ịhụ na nkwonkwo ahụ nwere otu ike dị ka ígwè isi, na okpomọkụ na-arụ ọrụ dị elu.A na-ejikarị Cu Mn co brazing filler metal maka brazing martensitic igwe anaghị agba nchara na ikuku nchebe.Ike nkwonkwo na okpomoku na-arụ ọrụ dị ka ndị ejiri ọla ndochi dabere na ọla edo.Dịka ọmụmaatụ, nkwonkwo igwe anaghị agba nchara 1Cr13 nke ejiri b-cu58mnco solder nwere otu arụmọrụ dịka otu nkwonkwo igwe anaghị agba nchara na b-au82ni solder (lee Tebụl 6), mana ọnụ ahịa nrụpụta na-ebelata nke ukwuu.

Tebụl 5 ike shiee nke 1Cr18Ni9Ti igwe anaghị agba nchara brazed na elu okpomọkụ isi ọla kọpa isi filler metal

Tebụl 6 ike shiee nke 1Cr13 igwe anaghị agba nchara brazed nkwonkwo

A na-eji ọla kọpa brazing dabere na Manganese maka mkpuchi mkpuchi gas, yana ịdị ọcha nke gas chọrọ ka ọ dị elu.Iji zere uto ọka nke metal base, a ga-ahọrọ metal brazing filler kwekọrọ na okpomọkụ brazing dị ala karịa 1150 ℃.Enwere ike nweta mmetụta brazing na-enye afọ ojuju maka nkwonkwo igwe anaghị agba nchara brazed na manganese dabeere solder, dị ka e gosiri na Tebụl 7. The ọrụ okpomọkụ nke nkwonkwo nwere ike iru 600 ℃.

Tebụl 7 ike shiee nke lcr18ni9fi igwe anaghị agba nchara brazed na manganese based filler metal

Mgbe igwe anaghị agba nchara na nickel base filler metal brazed, nkwonkwo nwere ezigbo okpomọkụ dị elu arụmọrụ.A na-ejikarị igwe ndochi a eme ihe maka brazing mkpuchi gas ma ọ bụ ihe mgbochi agụụ.Iji merie nsogbu ahụ na a na-emepụta ihe ndị ọzọ na-agbaji agbaji na nkwonkwo brazed n'oge nhazi nkwonkwo, nke na-ebelata ike na plasticity nke nkwonkwo ahụ, a ghaghị ibelata oghere nkwonkwo ahụ iji hụ na ihe ndị ahụ dị mfe ịmepụta oge na-agbaji agbaji na. solder na-n'ụzọ zuru ezu diffused n'ime isi metal.Iji gbochie ihe omume nke isi metal ọka uto n'ihi ogologo ijide oge na brazing okpomọkụ, usoro jikoro nke obere oge ejide na mgbasa ọgwụgwọ na ala okpomọkụ (tụnyere brazing okpomọkụ) mgbe ịgbado ọkụ nwere ike were.

Ngwongwo ihe eji eme akwa brazing metal a na-eji brazing igwe anaghị agba nchara gụnyere ọla edo edo edo na palladium nwere ọla filler, nke kachasị bụ b-au82ni, b-ag54cupd na b-au82ni, nke nwere ezigbo mmiri mmiri.The brazed igwe anaghị agba nchara nkwonkwo nwere elu elu okpomọkụ ike na ọxịdashọn-eguzogide, na kacha arụ ọrụ okpomọkụ nwere ike iru 800 ℃.B-ag54cupd nwere àgwà yiri nke b-au82ni na ọnụ ahịa ya dị ala, ya mere ọ na-achọ dochie b-au82ni.

(2) N'elu igwe anaghị agba nchara na flux na ọkụ ikuku nwere oxides dị ka Cr2O3 na TiO2, nke nwere ike wepụ naanị site na iji flux na ike ọrụ.Mgbe igwe anaghị agba nchara were tin lead solder jiri igwe anaghị agba nchara, mgbawa kwesịrị ekwesị bụ phosphoric acid aqueous solution ma ọ bụ zinc oxide hydrochloric acid solution.Oge ọrụ nke phosphoric acid aqueous ngwọta dị mkpụmkpụ, ya mere a ghaghị ịnakwere usoro brazing nke ikpo ọkụ ngwa ngwa.Enwere ike iji Fb102, fb103 ma ọ bụ fb104 fluxes maka brazing igwe anaghị agba nchara nwere ọla ọcha dabere na ọla.Mgbe brazing igwe anaghị agba nchara na ọla kọpa nke dabere metal filler, fb105 na-eji flux n'ihi na elu brazing okpomọkụ.

Mgbe ị na-eme brazing igwe anaghị agba nchara n'ọkụ, a na-ejikarị ikuku ikuku ma ọ bụ ikuku nchebe dị ka hydrogen, argon na decomposition amonia.N'oge a na-ekpochapụ oghere, nrụgide agụụ ga-adị ala karịa 10-2Pa.Mgbe ị na-eme brazing na ikuku nchebe, ebe igirigi nke gas agaghị adị elu karịa -40 ℃ Ọ bụrụ na ịdị ọcha gas ezughị ma ọ bụ brazing okpomọkụ adịghị elu, obere obere gas brazing flux, dị ka boron trifluoride, nwere ike. a ga-agbakwunye na ikuku.

2. teknụzụ brazing

A ghaghị ihicha igwe anaghị agba nchara nke ọma tupu brazing wepụ ihe ọ bụla griiz na ihe nkiri mmanụ.Ọ ka mma ịme braze ozugbo ihichachara.

Igwe anaghị agba nchara brazing nwere ike ịnakwere ire ọkụ, induction na oven usoro ikpo ọkụ.Igwe ọkụ maka brazing n'ime ọkụ ahụ ga-enwerịrị usoro njikwa okpomọkụ dị mma (a na-achọ ka ọ bụrụ ± 6 ℃ ngbanwe nke okpomọkụ) na enwere ike ịme ya ngwa ngwa.Mgbe a na-eji hydrogen dị ka gas na-echebe maka brazing, ihe ndị a chọrọ maka hydrogen na-adabere na okpomọkụ nke brazing na nhazi nke metal ala, ya bụ, na-ebelata okpomọkụ nke brazing, otú ahụ ka ígwè isi na-enwe stabilizer, na-ebelata igirigi. ebe hydrogen chọrọ.Dịka ọmụmaatụ, maka igwe anaghị agba nchara martensitic dị ka 1Cr13 na cr17ni2t, mgbe ị na-eme brazing na 1000 ℃, a chọrọ ka igirigi nke hydrogen dị ala karịa -40 ℃;Maka 18-8 chromium nickel igwe anaghị agba nchara na-enweghị stabilizer, ebe igirigi nke hydrogen ga-adị ala karịa 25 ℃ n'oge brazing na 1150 ℃;Otú ọ dị, maka 1Cr18Ni9Ti igwe anaghị agba nchara nwere titanium stabilizer, hydrogen igirigi ga-adị ala karịa -40 ℃ mgbe brazing na 1150 ℃.Mgbe brazing na nchekwa argon, ịdị ọcha nke argon chọrọ ịdị elu.Ọ bụrụ na a na-etinye ọla kọpa ma ọ bụ nickel n'elu igwe anaghị agba nchara, ihe a chọrọ maka ịdị ọcha nke mkpuchi gas nwere ike ibelata.Iji hụ na mwepụ nke ihe nkiri oxide n'elu igwe anaghị agba nchara, enwere ike ịgbakwunye flux gas BF3, a pụkwara iji lithium ma ọ bụ boron nwere ihe nchacha onwe ya.Mgbe vacuum brazing igwe anaghị agba nchara, ihe achọrọ maka ogo agụụ na-adabere na okpomọkụ brazing.Site na mmụba nke okpomọkụ brazing, enwere ike ibelata oghere achọrọ.

Usoro bụ isi nke igwe anaghị agba nchara mgbe brazing gasịrị bụ ihicha ihe ndị fọdụrụ na flux na ihe mgbochi mmiri, ma mee ọgwụgwọ okpomọkụ brazing ma ọ bụrụ na ọ dị mkpa.Dabere na usoro ịgbagharị na brazing a na-eji, enwere ike ịsacha mmiri nke fọdụrụ na mmiri, sachaa ya n'ụzọ igwe ma ọ bụ kpochaa ya na kemịkalụ.Ọ bụrụ na a na-eji abrasive na-ehicha ihe fọdụrụnụ ma ọ bụ ihe nkiri oxide na mpaghara ọkụ dị nso na nkwonkwo, a ga-eji ájá ma ọ bụ ihe ndị ọzọ na-adịghị mma.Akụkụ nke martensitic igwe anaghị agba nchara na mmiri ozuzo hardening igwe anaghị agba nchara chọrọ ọgwụgwọ okpomọkụ dị ka ihe pụrụ iche chọrọ nke ihe mgbe brazing.A na-emeso nkwonkwo igwe anaghị agba nchara nke nwere Ni Cr B na Ni Cr Si Filler metals na mgbasa ozi okpomọkụ mgbe brazing ga-ebelata ihe achọrọ maka oghere brazing ma melite microstructure na Njirimara nke nkwonkwo.

Oge nzipu: Jun-13-2022