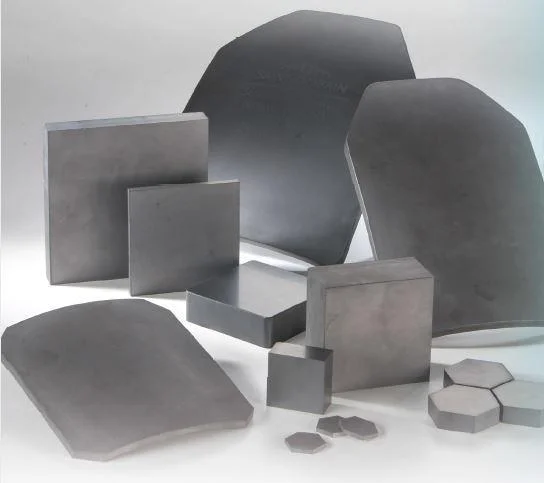

Silicon carbide ceramics nwere nnukwu okpomọkụ ike, elu okpomọkụ oxidation nguzogide, ezigbo eyi na-eguzogide, ezigbo thermal nkwụsi ike, obere ọnụọgụ nke thermal mgbasawanye, elu thermal conductivity, elu siri ike, okpomọkụ ujo eguzogide, chemical corrosion iguzogide na ndị ọzọ magburu onwe Njirimara.A na-eji ya eme ihe n'ọtụtụ ebe n'ime ụgbọ ala, nhazi ọrụ, nchebe gburugburu ebe obibi, nkà na ụzụ ikuku, ozi eletrọnịkị, ike na mpaghara ndị ọzọ, ma ghọọ seramiiki na-enweghị atụ na-arụ ọrụ nke ọma n'ọtụtụ ụlọ ọrụ mmepụta ihe.Ugbu a ka m gosi gị!

Sintering enweghị nrụgide

A na-ewere sintering enweghị nrụgide dị ka ụzọ kacha kwe nkwa maka ịmegharị SiC.Dị ka usoro nhịahụ dị iche iche si dị, enwere ike kewaa singing na-enweghị nrụgide n'ime usoro siri ike na nke mmiri mmiri.Site na ultra-fine β- A na-etinye ego kwesịrị ekwesị nke B na C (oxygen na-erughị 2%) na ntụ ntụ SiC n'otu oge, na s.Edebere proehazka n'ime ahụ siri ike nke SiC nwere njupụta dị elu karịa 98% na 2020 ℃.A. Mulla et al.A na-eji Al2O3 na Y2O3 mee ihe dị ka ihe mgbakwunye na sintered na 1850-1950 ℃ maka 0.5 μ m β-SiC (ihe dị n'elu nwere obere SiO2).Njupụta ikwu nke ceramics SiC nwetara karịrị 95% nke njupụta usoro ihe ọmụmụ, na nha ọka dị ntakịrị na nkezi nha.Ọ bụ 1.5 microns.

Hot pịa sintering

Enwere ike ịgbanye SiC dị ọcha naanị na oke okpomọkụ na-enweghị ihe mgbakwunye ọ bụla, yabụ ọtụtụ ndị na-eme usoro ịgbanye ọkụ ọkụ maka SiC.Enweela ọtụtụ akụkọ gbasara sntering na-ekpo ọkụ nke SiC site n'ịgbakwunye ihe enyemaka.Alliegro et al.Mụrụ mmetụta nke boron, aluminum, nickel, iron, chromium na ihe mgbakwunye ọla ndị ọzọ na njupụta SiC.Nsonaazụ na-egosi na aluminom na ígwè bụ ihe mgbakwunye kachasị dị irè iji kwalite SiC hot pressing sintering.FFlange mụrụ mmetụta nke ịgbakwunye ọnụọgụ dị iche iche nke Al2O3 na njirimara nke SiC na-ekpo ọkụ.A na-ewere na densification nke SiC na-ekpo ọkụ na-ekpo ọkụ metụtara usoro mgbasa na mmiri ozuzo.Otú ọ dị, usoro ikpo ọkụ na-ekpo ọkụ nwere ike ịmepụta akụkụ SiC nwere ọdịdị dị mfe.Ọnụ ọgụgụ nke ngwaahịa ndị a na-emepụta site na usoro ikpo ọkụ na-ekpo ọkụ nke otu oge dị ntakịrị, nke na-adịghị mma maka mmepụta mmepụta ihe.

Hot isostatic ịpị sintering

Iji merie adịghị ike nke usoro sintering ọdịnala, a na-eji ụdị B na ụdị C mee ihe dị ka ihe mgbakwunye na teknụzụ isostatic pressing sintering na-ekpo ọkụ nakweere.Na 1900 Celsius C, a nwetara ceramics dị mma nke nwere njupụta karịrị 98, na ike na-ehulata na ụlọ okpomọkụ nwere ike iru 600 MPa.Ọ bụ ezie na ọ na-ekpo ọkụ isostatic ịpị sintering nwere ike na-emepụta ok frasi ngwaahịa na mgbagwoju shapes na ezi n'ibu Njirimara, na sintering ga-akara, nke siri ike nweta ulo oru mmepụta.

Mmetụta mmeghachi omume

Reaction sintered silicon carbide, nke a makwaara dị ka silicon carbide nke onwe, na-ezo aka na usoro nke billet porous na-emeghachi omume na gas ma ọ bụ usoro mmiri mmiri iji melite ogo billet, belata porosity, na ngwaahịa emechara nke ọma na ike na nha nha.were α- SiC ntụ ntụ na graphite na-agwakọta n'otu akụkụ wee kpoo ọkụ ruo ihe dịka 1650 ℃ iji mepụta billet square.N'otu oge ahụ, ọ na-abanye ma ọ bụ banye n'ime billet site na gaseous Si na-emeghachi omume na graphite iji mepụta β-SiC, jikọtara ya na α-SiC dị adị.Mgbe etinyere Si n'ime ya kpam kpam, enwere ike nweta mmeghachi omume ahụ mebiri emebi na njupụta zuru oke yana nha na-enweghị mbelata.N'iji ya na usoro ndị ọzọ na-eme ka ọ bụrụ ihe na-eme ka ọ bụrụ ihe na-eme ka ọ bụrụ ihe na-eme ka ọ bụrụ ihe na-eme ka ọ dị ntakịrị, a pụkwara ịkwadebe ngwaahịa ndị nwere nha ziri ezi.Otú ọ dị, ịdị adị nke nnukwu SiC n'ime anụ ahụ na-eme ka ọ dịkwuo elu nke mmeghachi omume sintered SiC ceramics ka njọ.

Oge nzipu: Jun-08-2022