1. Ịkwụsị ike

Ọ na-esi ike braze seramiiki na seramiiki, seramiiki na metal components.Ọtụtụ n'ime ndị na-ere ahịa na-etolite bọọlụ n'elu seramiiki, na-enwe obere mmiri ma ọ bụ enweghị mmiri.Ihe nkpuchi brazing nke nwere ike ime ceramiki mmiri dị mfe ịmepụta ogige dị iche iche na-agbaji agbaji (dị ka carbide, silicides na ogige ternary ma ọ bụ multivariate) na nkwonkwo nkwonkwo n'oge brazing.Ịdị adị nke ogige ndị a na-emetụta ihe eji arụ ọrụ nke nkwonkwo.Tụkwasị na nke ahụ, n'ihi nnukwu ọdịiche dị iche iche nke mgbasawanye ọkụ n'etiti seramiiki, metal na solder, a ga-enwe nrụgide fọdụrụnụ na nkwonkwo mgbe brazing okpomọkụ dị jụụ na ụlọ okpomọkụ, nke nwere ike ime ka nkwonkwo nkwonkwo.

Enwere ike ime ka wettability nke onye na-ere ihe na seramiiki dị elu site n'ịgbakwụnye ihe ndị na-arụ ọrụ ígwè na ihe na-emekarị;Obere okpomọkụ na obere oge brazing nwere ike ibelata mmetụta nke mmeghachi omume interface;Enwere ike ibelata nrụgide okpomọkụ nke nkwonkwo site na ịmepụta ụdị nkwonkwo kwesịrị ekwesị na iji otu metal ma ọ bụ multi-layer dị ka oyi akwa nke etiti.

2. Solder

A na-ejikọkarị seramiiki na ígwè n'ime ọkụ ọkụ ma ọ bụ hydrogen na oven argon.Na mgbakwunye na njirimara izugbe, ọla brazing filler maka ngwaọrụ eletrọnịkị na-ekpo ọkụ kwesịrị inwe ụfọdụ ihe pụrụ iche chọrọ.Dịka ọmụmaatụ, onye na-ere ahịa ekwesịghị inwe ihe ndị na-emepụta nrụgide dị elu, ka ọ ghara ime ka dielectric leakage na nsị cathode nke ngwaọrụ.A na-akọwapụtakarị na mgbe ngwaọrụ ahụ na-arụ ọrụ, nrụgide vapor nke onye na-ere ahịa agaghị agafe 10-3pa, na oke ikuku ikuku dị n'ime ya agaghị agafe 0.002% ~ 0.005%;The w (o) nke ihe na-ere ahịa agaghị agafe 0.001%, ka ịzenarị ikuku mmiri a na-emepụta n'oge brazing na hydrogen, nke nwere ike ime ka ọkpụkpụ nke ígwè na-agbaze agbaze;Na mgbakwunye, ihe na-ere ahịa ga-adị ọcha na enweghị oxides elu.

Mgbe brazing mgbe seramiiki metallization, ọla kọpa, base, silver ọla kọpa, ọla kọpa na ndị ọzọ alloy brazing filler ọla nwere ike iji.

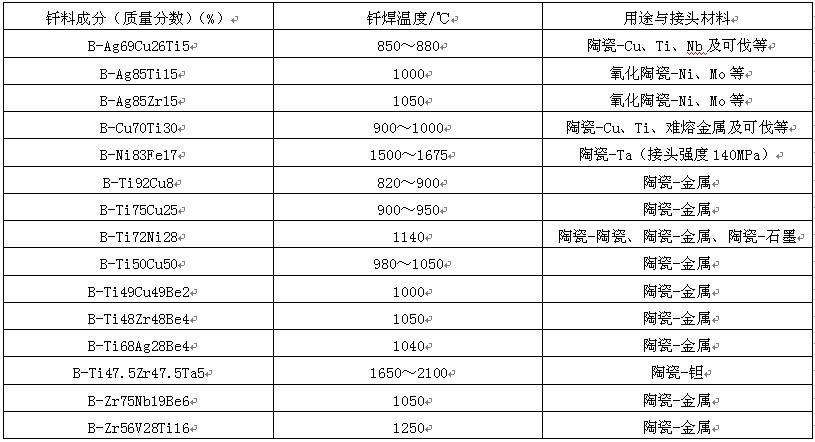

Maka brazing ozugbo nke seramiki na ọla, a ga-ahọrọ ọla brazing filler nwere ihe ndị na-arụ ọrụ Ti na Zr.Ọla ọnụọgụ ọnụọgụ abụọ bụ Ti Cu na Ti Ni, nke enwere ike iji na 1100 ℃.N'ime ternary solder, Ag Cu Ti (W) (TI) bụ ihe a na-ejikarị eme ihe, nke enwere ike iji maka brazing kpọmkwem nke ceramik na ọla dị iche iche.Enwere ike iji metal filler ternary site na foil, ntụ ntụ ma ọ bụ Ag Cu eutectic filler metal na Ti ntụ ntụ.B-ti49be2 brazing filler metal nwere nguzogide corrosion yiri nke igwe anaghị agba nchara yana nrụgide vapor dị ala.Enwere ike ịhọrọ ya nke ọma na nkwonkwo mkpuchi oghere na oxidation na nguzogide ntapu.Na ti-v-cr solder, okpomọkụ na-agbaze bụ nke kacha ala (1620 ℃) mgbe w (V) bụ 30%, na mgbakwunye nke Cr nwere ike ibelata okpomọkụ na-agbaze nke ọma.B-ti47.5ta5 solder na-enweghị Cr ejirila maka brazing kpọmkwem nke alumina na magnesium oxide, na nkwonkwo ya nwere ike ịrụ ọrụ na okpomọkụ nke 1000 ℃.Tebụl 14 na-egosi ngbanwe na-arụ ọrụ maka njikọ kpọmkwem n'etiti seramiiki na ígwè.

Tebụl 14 ọla brazing na-arụ ọrụ maka seramiiki na brazing metal

2. teknụzụ brazing

Enwere ike ịgbasa ceramik ndị a na-emebu metallized na gas inert dị ọcha dị elu, hydrogen ma ọ bụ ebe oghere.A na-ejikarị brazing Vacuum eme ihe maka brazing nke ceramik na-enweghị ọla.

(1) Universal brazing usoro usoro brazing zuru ụwa ọnụ nke seramiiki na ígwè nwere ike kewaa usoro asaa: nhicha elu, mkpuchi mado, seramiiki elu metallization, nickel plating, brazing na post weld nnyocha.

Ebumnuche nke ihicha elu bụ iji wepụ ntụpọ mmanụ, ọsụsọ na ihe nkiri oxide n'elu ala nke ígwè.A ga-ebu ụzọ kpochapụ akụkụ ígwè na ihe na-ere ahịa, mgbe ahụ, a ga-ewepụ ihe nkiri oxide site na acid ma ọ bụ alkali ịsacha, na-asa ya na mmiri na-asọ asọ ma kpoo ya.Akụkụ ndị nwere nnukwu ihe a chọrọ ga-ekpo ọkụ na ọkụ na-ekpo ọkụ ma ọ bụ ọkụ hydrogen (usoro bombardment ion nwekwara ike iji) na okpomọkụ na oge kwesịrị ekwesị iji mee ka elu akụkụ dị ọcha.Akụkụ ndị a kpochara agaghị ejikọta ya na ihe na-acha abụba ma ọ bụ aka efu.A ga-etinye ha ozugbo n'ime usoro ọzọ ma ọ bụ n'ime igwe nkụ.Agaghị ekpuchi ha na ikuku ruo ogologo oge.A ga-eji acetone na ultrasonic sachaa akụkụ seramiiki, jiri mmiri na-asọ asọ saa ya, ma mesịa sie ya ugboro abụọ na mmiri deionized maka 15min oge ọ bụla.

Ihe mkpuchi mado bụ usoro dị mkpa nke seramiiki metallization.N'oge mkpuchi, a na-etinye ya n'elu seramiiki ka a ga-eji brush ma ọ bụ ihe mkpuchi kpuchie ya.The mkpuchi ọkpụrụkpụ bụ n'ozuzu 30 ~ 60mm.A na-akwadebe tapawa ahụ site na ntụ ntụ dị ọcha (mgbe ụfọdụ a na-agbakwunye metal oxide kwesịrị ekwesị) yana nha nha nke ihe dịka 1 ~ 5um na nrapado organic.

A na-eziga akụkụ seramiiki ahụ mado n'ọkụ hydrogen ma were hydrogen dị mmiri ma ọ bụ amonia gbawara agbawa na 1300 ~ 1500 ℃ maka 30 ~ 60min.Maka akụkụ seramiiki nke ejiri hydrides kpuchie, ha ga-ekpo ọkụ ruo ihe dịka 900 ℃ iji mebie hydrides ma meghachi omume na metal dị ọcha ma ọ bụ titanium (ma ọ bụ zirconium) nke fọdụrụ n'elu seramiiki iji nweta mkpuchi ígwè n'elu seramiiki.

Maka oyi akwa metallized Mo Mn, iji mee ka ọ dị mmiri na ihe na-ere ya, a ga-etinyerịrị oyi akwa nickel nke 1.4 ~ 5um ma ọ bụ kpuchie ya na oyi akwa nickel ntụ ntụ.Ọ bụrụ na okpomoku brazing dị ala karịa 1000 ℃, ọ dị mkpa ka etinye ya na nickel oyi akwa n'ime ọkụ hydrogen.The sintering okpomọkụ na oge bụ 1000 ℃ / 15 ~ 20min.

Seramiki ndị a na-emeso bụ akụkụ ígwè, nke a ga-ejikọta ya na igwe anaghị agba nchara ma ọ bụ graphite na seramiiki.A ga-etinye solder na nkwonkwo, na workpiece ga-adị ọcha n'oge niile a na-arụ ọrụ, na a gaghị emetụ ya aka.

A ga-eme brazing na argon, hydrogen ma ọ bụ ọkụ ọkụ.Okpomọkụ brazing na-adabere na metal brazing filler.Iji gbochie mgbawa nke akụkụ seramiiki, ọnụego jụrụ oyi agaghị adị ngwa ngwa.Na mgbakwunye, brazing nwekwara ike itinye ụfọdụ nrụgide (ihe dịka 0.49 ~ 0.98mpa).

Na mgbakwunye na nlebanya ogo elu, weld brazed ga-adịkwa n'okpuru ujo ọkụ na nyocha akụrụngwa.Akụkụ akara maka ngwaọrụ oghere ga-adịkwa n'okpuru ule ntanye dịka iwu dị mkpa siri dị.

(2) Direct brazing mgbe ị na-eme brazing ozugbo (usoro igwe na-arụ ọrụ), buru ụzọ hichaa elu nke seramiiki na welding metal, wee kpokọta ha.Iji zere mgbawa site na ọnụọgụ mgbasawanye ọkụ dị iche iche nke akụrụngwa akụrụngwa kpatara, enwere ike ịtụgharị akwa mkpuchi (otu mpempe akwụkwọ ma ọ bụ karịa) n'etiti welding.A ga-ejigide ọla ndochi brazing n'etiti weld abụọ ma ọ bụ tinye ya n'ọnọdụ ebe oghere ahụ jupụtara na metal brazing dị ka o kwere mee, mgbe ahụ, a ga-eme brazing dị ka ihe mgbochi nkịtị.

Ọ bụrụ na a na-eji Ag Cu Ti solder maka brazing ozugbo, a ga-anakwere usoro ịgbatị oghere.Mgbe ogo agụụ na ọkụ ahụ ruru 2.7 × Malite kpo oku na 10-3pa, na okpomọkụ nwere ike ibili ngwa ngwa n'oge a;Mgbe okpomọkụ dị nso na ebe mgbaze nke ihe na-ere ahịa, okpomọkụ kwesịrị ịdị nwayọọ nwayọọ na-eme ka ọnọdụ okpomọkụ nke akụkụ niile nke weldment bụrụ otu;Mgbe agbazere ihe na-ere ahịa, a ga-ebuli okpomọkụ ngwa ngwa gaa na brazing okpomọkụ, na oge njide ga-abụ 3 ~ 5min;N'oge jụrụ oyi, a ga-eji nwayọọ nwayọọ mee ka ọ dị jụụ tupu 700 ℃, ma enwere ike ịme ya ka ọ dị mma na oven mgbe 700 ℃ gasịrị.

Mgbe Ti Cu na-arụ ọrụ solder na-agba ọkụ ozugbo, ụdị ihe na-ere ahịa nwere ike ịbụ Cu foil gbakwunyere Ti ntụ ntụ ma ọ bụ akụkụ Cu gbakwunyere Ti foil, ma ọ bụ seramiiki elu nwere ike iji Ti ntụ ntụ gbakwunyere Cu foil.Tupu ịkwa akwa, akụkụ ọla niile ga-ekpochapụ site na oghere.The degassing okpomọkụ nke oxygen free ọla kọpa ga-750 ~ 800 ℃, na Ti, Nb, Ta, wdg ga- degassed na 900 ℃ maka 15min.N'oge a, oghere oghere agaghị abụ ihe na-erughị 6.7 × 10-3Pa. N'oge brazing, chịkọta ihe ndị a ga-agbakọ na ntinye ahụ, kpoo ha na ọkụ ọkụ na 900 ~ 1120 ℃, na oge njide bụ 2 ~ 5min.N'oge usoro brazing dum, ogo agụụ agaghị erughị 6.7 × 10-3Pa.

Usoro brazing nke usoro Ti Ni yiri nke usoro Ti Cu, na brazing okpomọkụ bụ 900 ± 10 ℃.

(3) oxide brazing method oxide brazing method bụ usoro iji nweta njikọ a pụrụ ịdabere na ya site n'iji oge iko kpụrụ site na agbaze nke oxide solder iji banye n'ime seramiki na mmiri n'elu igwe.Ọ nwere ike ijikọ seramiki na seramiki na seramiki na ọla.Ọla oxide brazing bụ nke Al2O3, Cao, Bao na MgO mejupụtara.Site na ịgbakwunye B2O3, Y2O3 na ta2o3, enwere ike nweta ọla na-agbaze brazing nwere isi agbaze dị iche iche yana ọnụọgụ mgbasawanye ahịrị.Na mgbakwunye, fluoride brazing filler metals na CaF2 na NaF dị ka ihe ndị bụ isi nwekwara ike iji jikọọ ceramik na ọla iji nweta nkwonkwo nwere ike dị elu na oke okpomọkụ.

Oge nzipu: Jun-13-2022