Mgbochi nke Superalloys

(1) Enwere ike kewaa njirimara brazing superalloys ụzọ atọ: ntọala nickel, base iron na cobalt base.Ha nwere ezigbo ihe eji arụ ọrụ, nguzogide oxidation na nguzogide corrosion na oke okpomọkụ.Nickel base alloy bụ ihe a na-ejikarị eme ihe na mmepụta bara uru.

Superalloy nwere ọtụtụ Cr, na ihe nkiri Cr2O3 oxide nke siri ike iwepụ na-etolite n'elu n'oge okpomọkụ.Nickel base superalloys nwere Al na Ti, nke dị mfe oxidize mgbe ọkụ.Ya mere, iji gbochie ma ọ bụ belata oxidation nke superalloys n'oge kpo oku na iwepu ihe nkiri oxide bụ isi nsogbu n'oge brazing.Dị ka borax ma ọ bụ boric acid na flux nwere ike ime ka corrosion nke isi metal na brazing okpomọkụ, boron precipitated mgbe mmeghachi omume nwere ike banye n'ime isi metal, na-akpata intergranular infiltration.Maka ihe nkedo nickel base alloys nwere nnukwu ọdịnaya Al na Ti, ogo agụụ na steeti ọkụ agaghị abụ ihe na-erughị 10-2 ~ 10-3pa n'oge brazing iji zere oxidation na elu alloy n'oge kpo oku.

N'ihi na ihe ngwọta na-ewusi ike na ọdịda ike nickel base alloys ike, brazing okpomọkụ kwesịrị ikwekọ na kpo oku okpomọkụ nke ngwọta ọgwụgwọ iji hụ na mgbasa zuru ezu nke alloy ọcha.Okpomọkụ brazing dị oke ala, na ihe ndị na-emepụta alloy enweghị ike ịgbaze kpamkpam;Ọ bụrụ na okpomoku brazing dị oke elu, ọka metal ntọala ga-etolite, a gaghị eweghachi ihe onwunwe ahụ ọbụlagodi mgbe ọgwụgwọ okpomọkụ gasịrị.Okpomọkụ ngwọta siri ike nke ihe nkedo base alloys dị elu, nke n'ozuzu agaghị emetụta ihe onwunwe n'ihi oke ọkụ brazing.

Ụfọdụ nickel base superalloys, karịsịa mmiri ozuzo alloys siri ike, nwere ọchịchọ nke mgbawa nrụgide.Tupu brazing, a ga-ewepụrịrị nrụgide a na-emepụta na usoro a, ma belata nrụgide okpomọkụ n'oge brazing.

(2) Brazing ihe nickel base alloy nwere ike brazing na ọlaọcha ntọala, dị ọcha ọla kọpa, nickel base na arụ ọrụ solder.Mgbe okpomọkụ na-arụ ọrụ nke nkwonkwo adịghị elu, a pụrụ iji ihe ndị dabeere na ọlaọcha mee ihe.Enwere ọtụtụ ụdị ire ere ndị dabere na ọlaọcha.Iji belata nrụgide dị n'ime n'oge ikpo ọkụ brazing, ọ kacha mma ịhọrọ onye na-ere ahịa na obere okpomọkụ na-agbaze.Enwere ike iji Fb101 flux maka brazing na ọla ọcha nchacha ọla ọcha.A na-eji Fb102 flux maka mmiri ozuzo brazing siri ike na superalloy nwere ọdịnaya aluminom kachasị elu, yana 10% ~ 20% sodium silicate ma ọ bụ aluminom flux (dị ka fb201).Mgbe okpomọkụ brazing gafere 900 ℃, fb105 flux ga-ahọrọ.

Mgbe ị na-eme brazing na oghere ma ọ bụ ikuku nchebe, enwere ike iji ọla kọpa dị ọcha mee ihe dị ka igwe na-eju ihe brazing.The brazing okpomọkụ bụ 1100 ~ 1150 ℃, na nkwonkwo agaghị emepụta nchekasị cracking, ma na-arụ ọrụ okpomọkụ agaghị gafere 400 ℃.

Nickel base brazing filler metal bụ ihe a na-ejikarị brazing filler na Superalloys n'ihi na ọ na-arụ ọrụ okpomọkụ dị elu yana enweghị nchekasị ọ na-agbawa n'oge brazing.Ihe ndị bụ isi alloy na nickel base solder bụ Cr, Si, B, na obere ego na-ere ahịa nwekwara Fe, W, wdg. Tụnyere ni-cr-si-b, b-ni68crwb brazing filler metal nwere ike ibelata infiltration intergranular. nke B n'ime metal isi ma mee ka oge okpomọkụ na-agbaze.Ọ bụ igwe na-ejuputa brazing maka brazing akụkụ ọrụ na-ekpo ọkụ na turbine agụba.Otú ọ dị, fluidity nke W-nwere solder na-akawanye njọ na oghere nkwonkwo siri ike ịchịkwa.

Igwe nkpuchi brazing na-arụ ọrụ enweghị Si element ma nwee ezigbo nguzogide oxidation na nguzogide vulcanization.The brazing okpomọkụ nwere ike họrọ si 1150 ℃ ka 1218 ℃ dị ka ụdị solder.Mgbe brazing gasịrị, a ga-enweta nkwonkwo brazed nwere otu ihe dị ka metal ntọala mgbe ọgwụgwọ mgbasa 1066 ℃ gasịrị.

(3) Usoro brazing nickel base alloy nwere ike ịnakwere brazing na ọkụ ikuku na-echebe, ikuku brazing na njikọ mmiri na-agafe agafe.Tupu ịme brazing, a ga-ewepụrịrị elu ma wepụ oxide site na nchacha aja aja, na-achagharị ụkwụ ụkwụ, ncha acetone na ihicha kemịkal.Mgbe ị na-ahọrọ parampat usoro brazing, ekwesịrị ịdebe na okpomọkụ okpomọkụ ekwesịghị ịdị oke elu na oge brazing kwesịrị ịdị mkpụmkpụ iji zere mmeghachi omume kemịkalụ siri ike n'etiti flux na metal base.Iji gbochie nchara ígwè ahụ ka ọ ghara ịgbawa, akụkụ ndị a na-eme ka oyi na-atụ oyi ga-adị ka nrụgide tupu ịgbado ọkụ, na ikpo ọkụ na-ekpo ọkụ ga-abụ otu dị ka o kwere mee.N'ihi na mmiri ozuzo siri ike superalloys, akụkụ ga-n'okpuru siri ike ngwọta mbụ, wee brazed na okpomọkụ dịtụ elu karịa ịka nká ọgwụgwọ ike, na n'ikpeazụ ịka nká ọgwụgwọ.

1) Brazing na mkpuchi ikuku ikuku brazing na ọkụ ikuku na-echebe chọrọ ịdị ọcha dị elu nke mkpuchi gas.Maka superalloys nwere w (AL) na w (TI) ihe na-erughị 0.5%, ebe igirigi ga-adị ala karịa -54 ℃ mgbe ejiri hydrogen ma ọ bụ argon.Mgbe ọdịnaya nke Al na Ti na-abawanye, elu alloy ka na-ekpo ọkụ mgbe ọ na-ekpo ọkụ.A ga-emerịrị usoro ndị a;Tinye ntakịrị ntakịrị mmiri (dị ka fb105) wee wepụ ihe nkiri oxide na flux;0.025 ~ 0.038mm oké mkpuchi na-plated n'elu akụkụ;fesa ihe na-ere ihe n'elu ihe a ga-agbaze n'ihu;Tinye obere mmanụ ọkụ, dị ka boron trifluoride.

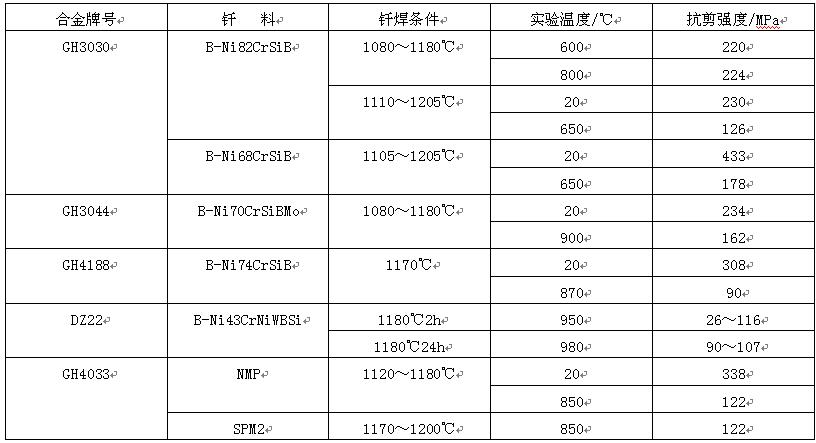

2) A na-eji Vacuum brazing vacuum brazing eme ihe n'ọtụtụ ebe iji nweta mmetụta nchebe ka mma yana mma brazing.Lee tebụl 15 maka ihe arụrụ arụ nke nkwonkwo nickel base superalloy.N'ihi na superalloys na w (AL) na w (TI) ihe na-erughị 4%, ọ ka mma electroplate a oyi akwa nke 0.01 ~ 0.015mm nickel n'elu, ọ bụ ezie na wetting nke solder nwere ike hụ na-enweghị pụrụ iche pretreatment.Mgbe w (AL) na w (TI) gafere 4%, ọkpụrụkpụ nke mkpuchi nickel ga-abụ 0.020.03mm.Ihe mkpuchi dị oke mkpa enweghị mmetụta nchebe, na oke mkpuchi ga-ebelata ike nke nkwonkwo.Enwere ike itinye akụkụ ndị a ga-agbado n'ime igbe maka ịgbado ọkụ.Igbe ahụ ga-ejupụta na gter.Dịka ọmụmaatụ, Zr na-etinye gas na okpomọkụ dị elu, nke nwere ike ịmepụta oghere mpaghara n'ime igbe ahụ, si otú a na-egbochi oxidation nke elu alloy.

Tebụl 15 akụrụngwa akụrụngwa nke Vacuum Brazed Joints nke ụdị nickel base superalloys

Microstructure na ike nke nkwonkwo brazed nke Superalloy na-agbanwe na ọdịiche nke brazing, na ọgwụgwọ mgbasa mgbe brazing ga-abawanye uru kachasị mma nke oghere nkwonkwo.Inweta Inconel alloy dị ka ihe atụ, oke oghere nke Inconel nkwonkwo brazed na b-ni82crsib nwere ike iru 90um mgbe mgbasa ọgwụgwọ na 1000 ℃ maka 1H;Otú ọ dị, maka nkwonkwo brazed na b-ni71crsib, kacha ọdịiche bụ banyere 50um mgbe mgbasa ọgwụgwọ na 1000 ℃ maka 1H.

3) Njikọ mmiri na-agafe agafe oge njikọ mmiri na-agafe agafe na-eji alloy interlayer (ihe dị ka 2.5 ~ 100um oké) nke ebe mgbaze ya dị ala karịa metal ntọala dị ka igwe ndochi.N'okpuru obere nrụgide (0 ~ 0.007mpa) na okpomọkụ kwesịrị ekwesị (1100 ~ 1250 ℃), ihe interlayer na-agbaze na-agbaze ma mee ka metal dị ala.N'ihi mgbasa ngwa ngwa nke ihe ndị dị na ya, isothermal solidification na-eme na nkwonkwo iji mepụta nkwonkwo.Usoro a na-ebelata nke ukwuu ihe kwekọrọ chọrọ nke elu metal ala ma belata nrụgide ịgbado ọkụ.Ihe ndị bụ isi nke njikọ usoro mmiri na-agafe agafe bụ nrụgide, okpomọkụ, oge njide na nhazi nke interlayer.Tinye obere nrụgide iji dobe elu nke welded na kọntaktị dị mma.Igwe ọkụ na-ekpo ọkụ na oge na-enwe mmetụta dị ukwuu na arụmọrụ nke nkwonkwo.Ọ bụrụ na a na-achọ ka nkwonkwo ahụ dị ike dị ka ihe mgbakwasị ụkwụ na-adịghị emetụta arụmọrụ nke metal ntọala, usoro njikọ njikọ nke oke okpomọkụ (dị ka ≥ 1150 ℃) na ogologo oge (dị ka 8 ~ 24h) ga-adị. nakweere;Ọ bụrụ na njirimara njikọ nke njikọ ahụ na-ebelata ma ọ bụ metal ntọala enweghị ike iguzogide okpomọkụ dị elu, a ga-eji obere okpomọkụ (1100 ~ 1150 ℃) na oge dị mkpirikpi (1 ~ 8h).N'etiti oyi akwa ga-ejikọrọ isi metal mejupụtara dị ka isi mejupụtara, na tinye dị iche iche jụrụ ihe, dị ka B, Si, Mn, Nb, wdg. Dị ka ihe atụ, mejupụtara Udimet alloy bụ ni-15cr-18.5co-4.3. al-3.3ti-5mo, na ihe mejupụtara oyi akwa etiti maka njikọ oge mmiri na-agafe agafe bụ b-ni62.5cr15co15mo5b2.5.Ihe ndị a niile nwere ike ibelata okpomọkụ na-agbaze nke Ni Cr ma ọ bụ Ni Cr Co alloys na nke kacha ala, mana mmetụta nke B bụ ihe doro anya.Na mgbakwunye, ọnụ ọgụgụ mgbasa ozi dị elu nke B nwere ike ime ngwa ngwa homogenize interlayer alloy na metal base.

Oge nzipu: Jun-13-2022