Ọkụ na-ekpochapụ Vacuum na ọkụ ọkụ (MIM Furnace, Ọkụ ọla ntụ ntụ)

Njirimara

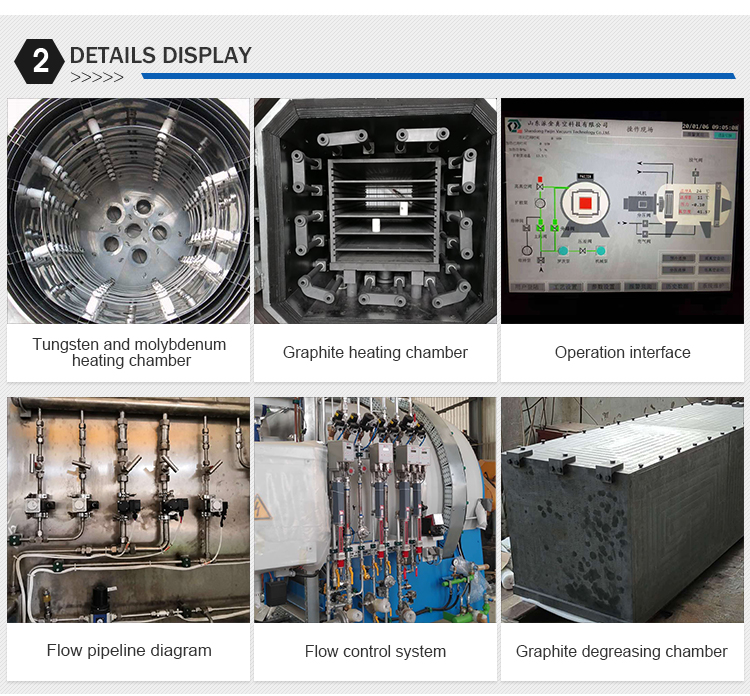

1. Ihe nkpuchi mkpuchi graphite / nhọrọ ihuenyo metal, ihe na-ekpo ọkụ 360 degrees gburugburu radieshon kpo oku, a pụrụ ịdabere na mkpuchi imewe.

2. Higher okpomọkụ uniformity na thermal arụmọrụ

3. Vacuum akụkụ akụkụ nrụgide / ọrụ njikwa okpomọkụ nke ọtụtụ mpaghara.

4. Ngwá ọrụ akpaaka zuru oke, nchekwa zuru oke na usoro mkpu na-adịghị mma.

5. Njikwa usoro ziri ezi iji nweta ịdị mma akụkụ na-agbanwe agbanwe ma gbochie mmetọ nke akụkụ na ebe ọkụ.

6. Na igbe degreasing mechiri emechi na oghere condenser iji belata mmetọ nke ụlọ kpo oku na otu.

7.Prevent mmetọ na components na ọkụ. The square degenreasing igbe na-eji nagide ọnụ ọgụgụ buru ibu nke ịkpụzi ihe mgbakwunye.

8. Ọ nwere ọrụ nke mmịpụta oghere na-agbanwe agbanwe, vacuum sintering, micro-positive pressure sintering na na.

9. A na-eji usoro ihe mkpuchi ọkụ kachasị ọhụrụ na ihe eji eme ihe, nrụgide nrụgide siri ike, na nchekwa ike pụtara ìhè.

10.It nwere ọrụ nke overtemperature na overpressure mkpu, n'ibu akpaka nrụgide nchedo, akpakanchebe enyemaka overpressure, ime ihe na ihe ndị ọzọ, nchekwa akụrụngwa dị elu.

11.Remote ọrụ, remote mmejọ nchoputa na remote software nkwalite ọrụ, wdg.

Standard ụdị nkọwapụta na parameters

| Nlereanya | PJSJ-gr-30-1600 | PJSJ-gr-60-1600 | PJSJ-gr-100-1600 | PJSJ-gr-200-1600 | PJSJ-gr-450-1600 |

| Mpaghara ọkụ dị irè LWH (mm) | 200*200* 300 | 300*300* 600 | 300*300* 900 | 400*400*1200 | 500*500* 1800 |

| Ibu ibu(kg) | 100 | 200 | 400 | 600 | 10000 |

| Ike ikpo oku (kw) | 65 | 80 | 150 | 200 | 450 |

| Okpomọkụ kachasị (℃) | 1600 | ||||

| Izi ezi njikwa okpomọkụ (℃) | ±1 | ||||

| Ịdị n'otu ọkụ ọkụ (℃) | ±3 | ||||

| Ogo vacuum ọrụ (Pa) | 4.0 * E-1 | ||||

| Ọnụ ego mgbapụta (ruo paa 5) | ≤10 min | ||||

| Ọnụego mbuli nrụgide (Pa/H) | ≤0.5 | ||||

| Ọnụ ego nkwụnye ego | 97.5% | ||||

| Usoro nbipụta | N2 na nrụgide na-adịghị mma, H2 na ikuku | ||||

| Ntinye gas | N2, H2, Ar | ||||

| Usoro jụrụ oyi | inert gas jụrụ | ||||

| Usoro ịgbakọ | Vacuum sintering, akụkụ ụfọdụ nrụgide sintering, enweghị nrụgide sintering | ||||

| Ọdịdị ọkụ | Kehoraizin, otu ọnụ ụlọ | ||||

| Ụzọ oghere ụzọ ọkụ | Ụdị hinge | ||||

| Ihe na-ekpo ọkụ | Ihe ndị na-ekpo ọkụ eserese | ||||

| Ụlọ ọkụ | Nhazi nhazi nke eserese eserese siri ike na mmetụta dị nro | ||||

| Thermocouple | Ụdị C | ||||

| PLC & igwe eletrik | Siemens | ||||

| Onye na-ahụ maka okpomọkụ | EUROTHERM | ||||

| Mgbapu mgbapụta | Mechanical mgbapụta na mgbọrọgwụ mgbapụta | ||||

| Oke nhọrọ ahaziri | |||||

| Okpomọkụ kachasị | 1300-2800 ℃ | ||||

| Ogo ogo kachasị elu | 6.7 * E-3 Pa | ||||

| Ọdịdị ọkụ | Kehoraizin, kwụ ọtọ, otu ọnụ ụlọ | ||||

| Ụzọ mmeghe ọnụ ụzọ | Ụdị mgbanaka, Ụdị ebuli, Ụdị dị larịị | ||||

| Ihe na-ekpo ọkụ | Ihe ndị na-ekpo ọkụ eserese, Mo kpo oku | ||||

| Ụlọ ọkụ | Ederede graphit chere, All metal na-egosipụta ihuenyo | ||||

| Mgbapu mgbapụta | Mechanical mgbapụta na mgbọrọgwụ mgbapụta; Mechanical, Mgbọrọgwụ na nfuli mgbasa ozi | ||||

| PLC & igwe eletrik | Siemens; Ọmrọn; Mitsubishi; Siemens | ||||

| Onye na-ahụ maka okpomọkụ | EUROTHERM;S HIMADEN | ||||